Precision Isola PCB Manufacturer for

High-Performance Applications

WellPCB is an Isola PCB manufacturer for aerospace, automotive, telecommunications and medical applications requiring superior thermal performance and signal integrity.

Each Isola PCB is engineered using premium laminate materials including Isola 370HR, fabricated to IPC Class 3 standards, and supported with our complete PCB assembly services.

Our two PCB manufacturing factories in Shenzhen and Jiangmen process the complete range of Isola laminate materials from standard multilayer PCB designs to complex HDI configurations.

- Isola 370HR, FR408HR, and high frequency laminate processing.

- Certified ISO 9001:2015, UL listed, and IPC-certified manufacturing.

- 1 to 64 layer capability with controlled impedance and 3/3 mil trace/space routing.

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

- PCB Manufacturer

- Isola

Isola PCB Manufacturing for High-Performance Applications

Isola PCBs are widely used in RF power amplifiers, satellite communications, electric vehicle inverters and medical diagnostic equipment where standard FR-4 material cannot meet performance requirements.

These Isola laminate materials enable complex routing patterns across multilayer PCB configurations while maintaining stable dielectric properties and thermal conductivity under extreme operating conditions.

Isola has been around since 1912 and now has 10 manufacturing sites and 3 R&D facilities worldwide.

WellPCB processes Isola PCB constructions with material characterization, stack up validation, and thermal modeling expertise in mind, whether you’re developing an Isola PCB for qualification testing or transitioning to volume PCB manufacturing.

Our Isola PCB manufacturer operations utilize specialized lamination equipment for processing Isola materials, including Isola FR408, prepreg materials, and copper clad laminates, with temperature-controlled curing, void-free bonding, and dimensional stability verification.

Isola PCB material specifications are validated through glass transition temperature testing before laminate bonding and verified post-processing through microsection analysis.

Components like dielectric material layers and etched laminate circuits are examined for defects and conformance.

Our Isola PCB Manufacturing Capabilities

Our Isola PCB manufacturer facilities process Isola laminate materials using controlled temperature lamination, precision drilling and validated thermal cycling for aerospace, automotive, and telecommunications applications.

We support multilayer PCB constructions of up to 64 layers using Isola 370HR and Isola FR408, along with high-performance material processing, including the integration of copper clad laminates and complete PCB assembly traceability.

We, as a leading Isola PCB manufacturer, fabricate PCB boards using vacuum lamination presses with temperature control of ±4°F (±2°C) and pressure regulation from 200 to 250 PSI, positioning prepreg materials between copper clad laminates with precise registration.

Laminate and prepreg materials are selected based on their glass transition temperature (Tg), coefficient of thermal expansion (CTE), and resin content to ensure PCB construction dimensional stability across operating ranges of -40°F to 302°F (-40°C to 150°C).

Layer-to-layer registration maintains tight accuracy through optical alignment systems and fiducial tracking, ensuring that Isola PCB trace routing used meets 3 mil line/space requirements for high-density interconnects.

Mechanical drilling operations use carbide tooling to achieve hole diameters from 6 mil to 250 mil (0.15mm to 6.35mm) with aspect ratios up to 25:1 on Isola material substrates (up to 12:1 on 370HR depending on board thickness and via size).

Laser drilling systems operate at UV wavelengths for microvia formation, with a minimum diameter of 3 mil (0.075 mm), maintaining positional accuracy within ±0.6 mil (±15 μm) for high density interconnect (HDI) applications on printed circuit boards.

Via processing includes plasma desmear at controlled power settings and chemical etching with permanganate solutions optimized for Isola PCB material resin removal and copper adhesion enhancement.

Isola PCB surface treatments use immersion processes with controlled bath chemistry: ENIG with 0.05 to 0.1 μm gold over 120 to 240 μm nickel, and OSP with 8 to 20 μm (0.2 to 0.5 μm) organic coating thickness.

Electroless nickel immersion gold (ENIG) processing maintains a bath pH of 4.5 ± 0.1 and a temperature of 190°F ± 4°F (88°C ± 2°C) for materials used in PCB manufacturing that require multiple reflow cycles.

Heavy copper electroplating achieves a finished thickness of 20 oz using current densities of 15 to 25 ASF, with plating uniformity within ±10% across PCB panel surfaces.

Controlled impedance manufacturing utilizes field solver modeling and maintains single ended impedance of 50Ω ± 5Ω and differential pairs at 100Ω ± 10% through dielectric thickness control of ±0.3 mil (±8%).

370HR Isola PCB constructions achieve trace width and spacing down to 3/3 mil, with a copper thickness variation of ≤ ±10% for Isola PCB applications requiring consistent signal propagation.

Time domain reflectometry (TDR) testing validates impedance performance across dielectric material layers with a measurement accuracy of ±2% for PCB design verification.

Component placement uses vision-guided systems with ±1 mil (±25 μm) accuracy, supporting PCB assembly of 01005 components, 8 mil (0.2mm) pitch BGAs, and 6 mil (0.15mm) QFP lead spacing on advanced PCB constructions.

In circuit testing (ICT) uses flying probe systems with 2 mil (50 μm) probe accuracy and fixture-based testers that can accommodate over 20,000 test points for comprehensive electrical validation of Isola substrates.

Automated optical inspection (AOI) systems operate at 0.4 mil (10 μm) resolution with machine learning algorithms detecting solder joint defects, component placement errors, and PCB fabricators quality deviations.

Thermal cycling testing subjects multilayer PCB applications to -85°F to 302°F (-65°C to 150°C) transitions with 15-minute dwell times and 500-1000 cycle validation per IPC-TM-650 Method 2.6.7.

Highly accelerated stress testing (HAST) operates at 266°F (130°C) and 85% relative humidity for 96 to 1000 hours, evaluating the long term reliability performance of Isola PCBs.

Salt spray testing, as per ASTM B117 standard, exposes PCB construction to a 5% sodium chloride solution for 48 to 240 hours, validating corrosion resistance for harsh environment deployment.

WellPCB is a Isola PCB manufacturer that creates flexible PCB circuits using polyimide materials with thicknesses ranging from 0.05-0.5 mm (Ultimate:0.5-0.8 mm) and layer counts of 1 to 4 layers (with a maximum of 5 to 8 layers), as well as copper weights from 0.33 oz to 2 oz, for PCB applications that require dynamic bending.

Isola PCB rigid-flex constructions combine flexible sections with rigid multilayer PCB areas, supporting panel sizes ranging from 0.4” × 0.6” (10 mm × 15 mm) to 16” × 29” (406 mm × 736 mm), using Isola prepreg materials for seamless transition zones.

Here’s Why WellPCB Should Be Your First Choice Isola PCB Manufacturer

WellPCB is a reliable Isola PCB manufacturer, owning fully equipped facilities, specialized Isola material processing, and comprehensive quality systems for demanding printed circuit board applications.

Own Manufacturing Facilities

This vertical integration allows direct oversight of laminate material inventory, process controls, and quality systems, ensuring consistent PCB construction standards across all Isola PCB applications.

Scalable Production Capacity

Load balancing between our Isola PCB manufacturing facilities ensures consistent delivery times for multilayer PCB and advanced PCB projects, regardless of order size or production volume requirements.

Fast Turnaround

Express processing includes expedited material procurement, priority queue scheduling, and dedicated production line allocation to meet tight project deadlines for printed circuit board requirements.

Component Integrity Guarantee

Incoming component inspection includes authenticity verification, electrical testing, and validation of the moisture sensitivity level before PCB assembly processing.

Component storage utilizes controlled temperature and humidity environments, along with dry packing procedures, to maintain the integrity of materials for PCB manufacturing throughout the assembly process.

Design Review

Pre-production review services include manufacturability assessment, laminate material compatibility verification, and process optimization recommendations to ensure Isola PCB applications can be built efficiently and reliably.

Reliable Global Shipping

Packaging protocols protect PCB boards during transit using anti static materials, moisture barrier bags, and impact resistant containers suitable for Isola substrate sensitivity requirements.

Industries We Serve as an Isola PCB Manufacturer

WellPCB serves the aerospace, automotive, telecommunications and medical device industries with Isola PCB manufacturing tailored to your specific requirements and the performance and regulatory requirements of each sector.

Aerospace Applications

Automotive Electronics

5G & Telecommunications Infrastructure

Medical Device Manufacturing

Industrial Equipment

What is Isola PCB?

An Isola PCB is a printed circuit board manufactured using laminate materials and prepreg materials developed by the Isola Group, a materials science company specializing in copper clad laminates for electronic applications.

Isola PCB material consists of dielectric material layers with copper foil bonded together using a specialized resin system of Isola PCB formulations that create the PCB construction. The material used in Isola PCB manufacturing includes epoxy resin systems and glass fabric reinforcement processed into copper clad laminates and dielectric prepregs for multilayer PCB production.

What are the Differences Between Isola PCB and FR-4 Material?

Isola PCB materials handle much higher temperatures (338°F vs 266°F), provide superior electrical performance with lower signal losses, offer better mechanical strength, and cost significantly more than standard FR-4 material.

FR-4 material is the basic, affordable PCB material for general electronics, while Isola material like 370HR is a premium, high performance material option with advanced resin systems for demanding applications.

Both materials use glass-fiber reinforced epoxy resin systems, but the materials used in Isola PCB are engineered variants designed for aerospace, automotive, and high frequency PCB applications where standard FR-4 material performance isn’t sufficient. Isola materials achieve glass transition temperatures up to 500°F and enhanced thermal conductivity compared to basic FR-4 material.

The electrical differences become important in high speed designs: Isola PCB materials show lower dielectric constants and dissipation factors at high frequencies, making them ideal for PCB applications requiring superior signal integrity. Standard FR-4 material remains the preferred choice for cost-sensitive projects due to its significantly lower cost and wide availability.

| Property | Isola PCB Materials | FR-4 Material |

|---|---|---|

| Material Type | Premium high-performance material from Isola | Standard epoxy fiberglass laminate material |

| Glass Transition Temperature | 338°F to 500°F (170°C to 260°C) | ~266°F (130°C) |

| Thermal Performance | Superior heat resistance (Isola 370HR) | Basic thermal performance |

| Electrical Properties | Better signal integrity, lower loss | Good for general use |

| Dielectric Constant | 2.2 to 4.6 (varies by Isola material) | ~4.2 |

| Applications | High frequency PCB, aerospace, automotive | General electronics, consumer products |

| Signal Loss | Much lower for the materials used in Isola PCB | Higher loss at high frequencies |

What Should You Consider When Designing Isola PCBs?

As an Isola PCB manufacturer, you should consider Isola PCB laminate selection, dielectric properties of Isola, signal routing, and coordination with PCB fabricators to ensure optimal performance when designing Isola PCBs.

Material Selection

Stack Up Planning

Signal Integrity

Thermal Management

Component Placement

Multilayer Design

How to Order Isola PCB from WellPCB

Submit Your PCB Design

Upload your Gerber files or use our easy online PCB design tool to create your board layout. Make sure your files are complete and correctly formatted to ensure smooth processing and production accuracy.

Select Your PCB Specifications

Customize your order by choosing the technical specifications—number of layers, board dimensions, thickness, copper weight, solder mask color, surface finish, and more. Our intuitive interface helps you configure everything based on your project’s needs.

Get an Instant Quote

Once your design and specs are in place, you'll receive a transparent, instant quote. Pricing updates in real time as you modify options, so you can adjust your selections to match your budget before placing the order.

Confirm Order & Make Payment

Review your entire order for accuracy, including file previews and selected specs. After confirmation, proceed to secure checkout and choose your preferred payment method. You’ll receive an email confirmation with order details.

Production & Delivery

Your PCB moves into production immediately. We’ll keep you updated throughout the manufacturing process. Once completed, your boards are carefully packed and shipped to your door, with tracking information provided for your convenience.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB?

WellPCB stands out among USA PCB manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top PCB manufacturers in USA.

WellPCB specializes in multilayer PCBs for advanced electronic applications. You can order these boards with $100 off using our special offer, providing high complexity at competitive rates for demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

Isola PCB Case Studies

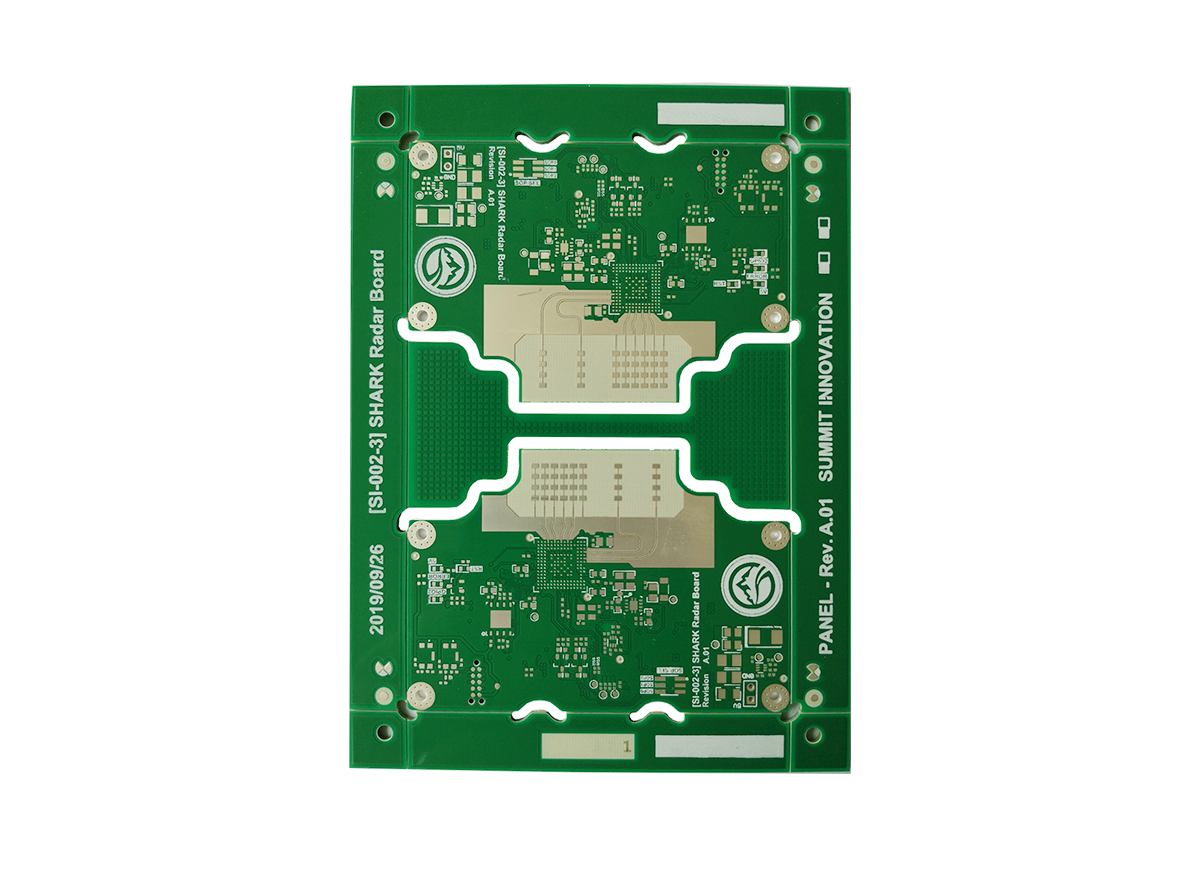

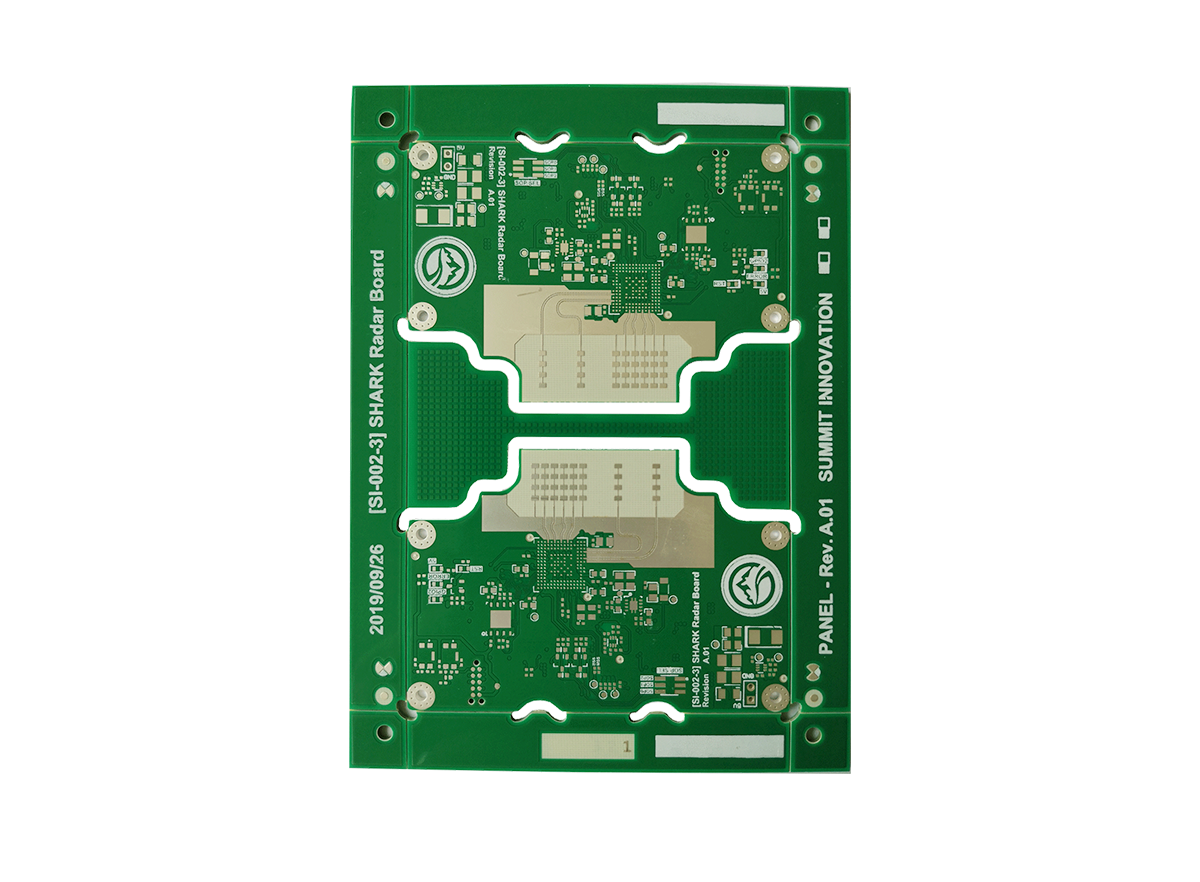

PCB Assembly

This project is the Isola board we produced before. It meets the requirements of high frequency and high speed at the same time; high frequency and high speed circuit boards play a vital role in modern electronic devices, such as 5G communications, high performance computing, automotive electronics, etc.

Features:

- •Layers: 6 Layers

- •Product features: RO4835+Isola370HR(Mix pressing)

- •Blind vias

- •Vias on Pad

- •Impedance control

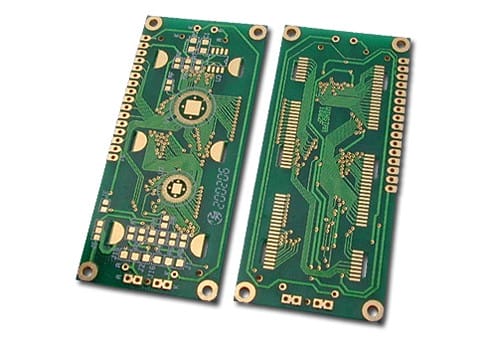

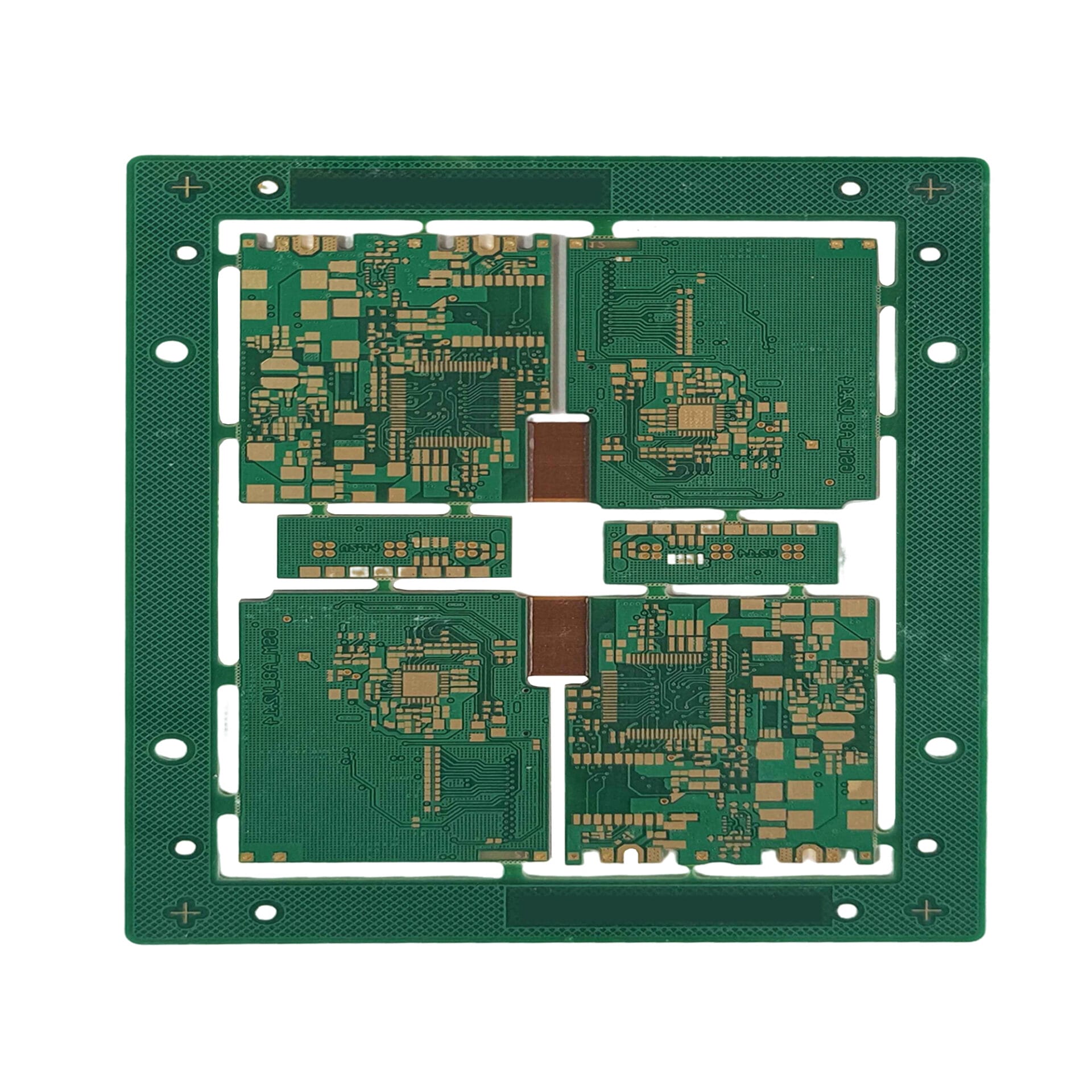

PCB Assembly

This project showcases a 6-layer HDI Rigid-flex PCB, engineered with a hybrid Isola + PI stack-up.

Features:

- •Layers: 2 layers Flex

- •Product features: Impedance control on flex area

- •PI+Isola

- •Min.line width/space:4/4mil

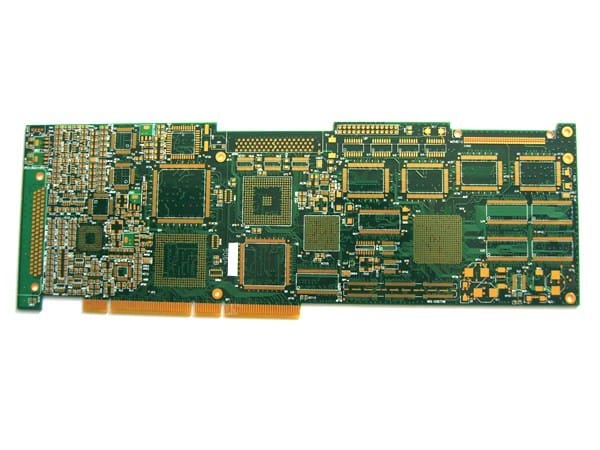

PCB Assembly

This project is a highTG+Isola mix pressing board, which used for Industry.

Features:

- •Layers: 8 Layers

- •Features: Inner layer hole to line

- •Isola+HighTG mix pressing

- •Thickness: 1.8mm

- •Special process: Gold finger

Client Feedback On WellPCB Isola PCB Manufacturer

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

Isola PCB Manufacturer FAQs

What triggers outgassing in Isola dielectric materials?

Outgassing in Isola material occurs from residual moisture in prepreg materials, incomplete curing of Isola PCB’s resin system, and volatile compounds trapped during processing. WellPCB minimizes this through proper pre-bake cycles and controlled humidity during Isola PCB fabrication.

Can you mix different Isola materials in the same multilayer PCB?

Yes, multilayer Isola PCB constructions can combine different types of Isola materials like Isola 370HR and 408HR in the same stackup. PCB fabricators must ensure compatible thermal expansion coefficients and cure temperatures when mixing materials used in Isola PCB to prevent delamination during PCB construction.

What's the maximum aspect ratio you can drill in Isola 370HR material?

We achieve aspect ratios up to 12:1 in 370HR Isola PCB constructions using specialized carbide tooling optimized for Isola material characteristics. PCB fabricators must adjust drill speeds and feed rates for Isola PCB material to prevent smearing and ensure clean hole walls in multilayer Isola PCB applications.

How do you prevent copper peel during Isola PCB etching?

As a reliable Isola PCB manufacturer, we use modified etching parameters and controlled etchant chemistry to prevent copper peel in Isola material.

Etched laminate processing requires specific temperature control and post-etch treatments for Isola PCB’s resin system to maintain strong copper adhesion in materials used in Isola PCB while achieving precise trace geometries for high-performance PCB designs.

Partner with a High Quality Isola PCB Manufacturer for High Quality Results

Get $100 Off Your First Order!

Isola products that meet industry regulations and stand up to high pressure and high temperature applications. Contact us, get a free quote, and get a discount on your first order!