One Stop PCB Assembly Services for

Complex Electronic Manufacturing

One stop PCB assembly services integrate both fabrication and assembly processes to deliver complete electronic manufacturing solutions from prototype PCB to volume production across multiple industries.

WellPCB operates two PCB manufacturing factories in Shenzhen and Jiangmen plus two assembly factories in Shenzhen and Shijiazhuang with ISO9001:2008 certifications.

Our service includes SMT assembly, through-hole assembly, and turnkey solutions with global component sourcing from authorized distributors like Arrow, Avnet and Future Electronics.

- Single/double side SMT and through-hole assembly.

- Global component sourcing from authorized distributors.

- Complete turnkey solutions from fabrication to box build.

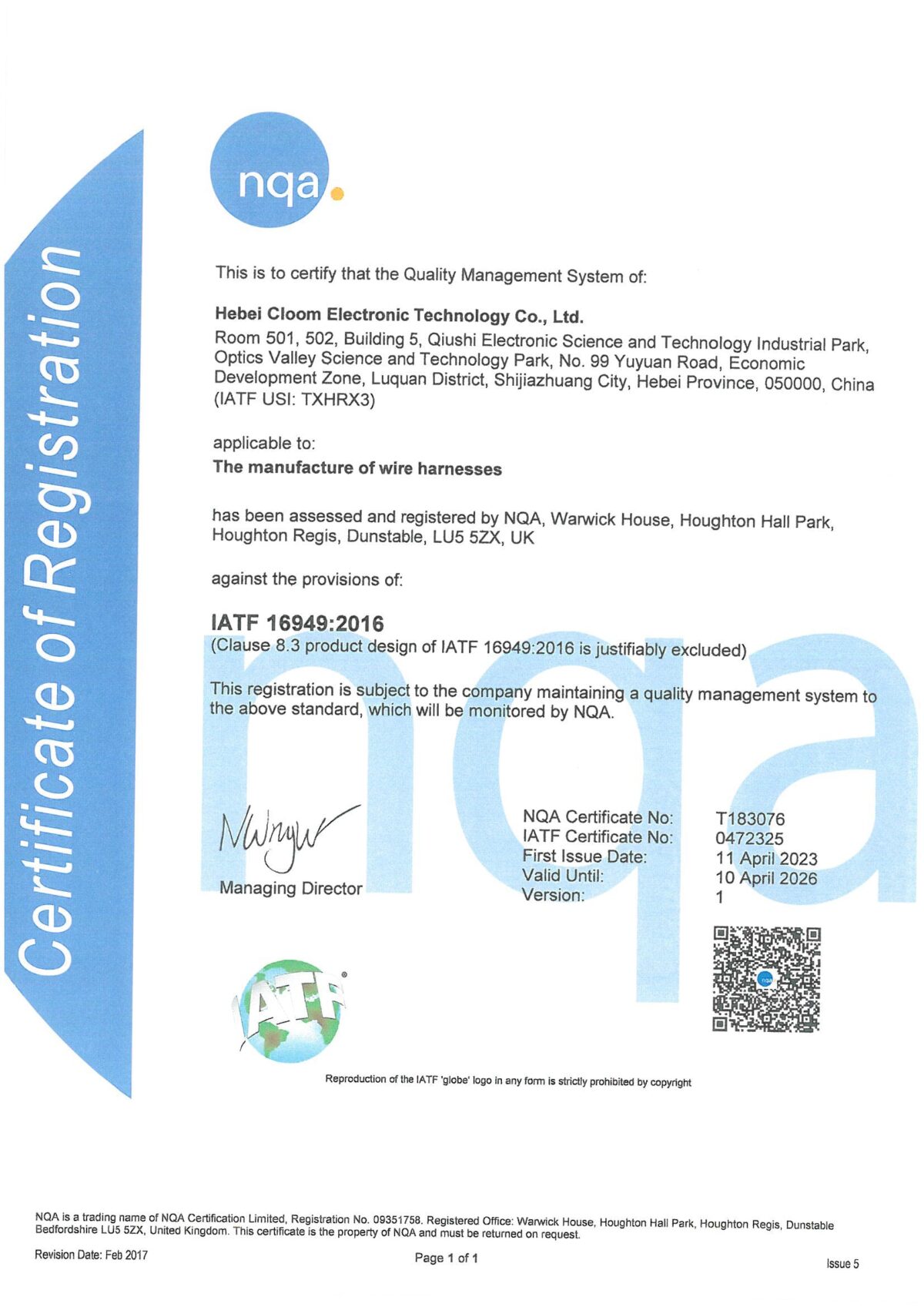

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

- PCB Manufacturer

- PCB Assembly Service

- One Stop

Complete One Stop Solutions for PCB Fabrication and Assembly

One-stop PCBA solutions are used in automotive control modules, medical monitoring devices, telecommunications infrastructure and industrial automation systems.

Every circuit board receives component placement, soldering, and functional test verification under ISO9001:2008 quality standards.

WellPCB processes Isola PCB constructionsWellPCB provides turnkey PCB solutions with BOM management, stencil creation, and pick-and-place operations. We also provide box build assembly for complete electronic products.

Our one stop PCB assembly services include visual inspection, AOI inspection and X-ray analysis capabilities. Each PCBA is processed for signal integrity and thermal performance across demanding environments.

Components and PCB board configurations undergo surface mount placement, solder paste printing, and controlled reflow cycles. These create reliable interconnections around fine-pitch ICs, BGAs, and high-density layouts.

Our One Stop PCB Assembly Services Capabilities

WellPCB delivers comprehensive assembly capabilities for printed circuit board assembly projects, combining stencil creation, solder paste application and reflow processing under controlled assembly process conditions.

Each PCBA undergoes assembly and testing verification across PCBA process stages before release from our ISO9001:2008 certified factory locations.

PCB fabrication processes accommodate 1 to 32 layer PCBs with finished printed circuit board thickness from 0.2 mm to 6.0 mm.

FR4 standard materials support PCB manufacturing alongside high Tg variants, Rogers HF materials, aluminum metal core, copper core, and ceramic substrates for advanced PCB applications.

Our PCB manufacturer capabilities maintain a high level of precision while minimum trace width and spacing achieve 3mil resolution across custom PCB designs.

SMT assembly operations handle electronic components from 01005 miniaturized devices through large BGA assembly arrays with a minimum 0.3mm pitch capability.

Surface mount technology placement uses stencil printing for solder paste application before component positioning.

Reflow ovens operate with nitrogen atmosphere control, maintaining placement accuracy within ±30µm under 3σ conditions.

SMT processing throughput reaches 600,000 chips per hour for high quality PCB production.

Wave soldering systems process standard through-hole components with selective soldering targeting specific areas requiring thermal isolation.

THT assembly includes manual soldering stations that handle mixed assembly requirements and unconventional component geometries.

Through-hole solder joint quality follows IPC-A-610 acceptance criteria for PCB assemblies requiring robust mechanical connections.

SMT and THT integration supports complex PCBA designs requiring multiple assembly technologies within one manufacturing process.

Blind, buried, and microvias achieve a minimum 0.1mm diameter through laser drilling processes for PCB density optimization.

Via-in-pad configurations enable compact PCB layout while controlled impedance routing maintains signal integrity across circuit boards.

3D AOI systems perform solder joint optical inspection with automated defect classification for quality and precision validation. X-ray inspection verifies BGA solder ball integrity and voiding analysis beneath electronic components.

In-circuit testing validates electrical connectivity while functional test equipment confirms operational performance. Assembly testing protocols include X-ray analysis for hidden solder defects.

Authorized distributor partnerships include Digi-Key, Mouser Electronics, Avnet, Arrow Electronics and Future Electronics for global electronic components availability.

BOM optimization service analyzes component lifecycles while BOM management recommends alternatives and implements obsolescence mitigation strategies.

Component sourcing supports prototypes through volume PCB production requirements.

Cable assembly and wire harness integration complement PCB and PCBA service offerings for complete system builds.

Box build assembly includes mechanical housing integration, labeling and ESD-safe packaging that prepares electronic products for final shipment.

System-level functional testing confirms end-product performance while value added services support complete electronic assemblies.

PCB prototype fabrication delivers finished prototype PCB boards within 2 weeks for fast development schedules with reduced lead time.

Prototype assembly service includes Design for Manufacturing (DFM) analysis that optimizes PCB design layouts for production efficiency.

New Product Introduction (NPI) support accommodates 1 to 100 piece pilot builds with dedicated engineering teams managing prototype to production transitions.

Why Choose WellPCB for your One Stop PCB Assembly Services?

Choose WellPCB because we eliminate coordination headaches between separate PCB and assembly vendors through unified project management. Our four strategically located facilities reduce shipping costs while direct manufacturer relationships provide priority access to electronic components during supply shortages.

One Stop Convenience

Our one stop approach means you get PCB fabrication, component sourcing, and assembly services through one vendor contact instead of coordinating multiple suppliers.

Manufacturing Optimization

Our manufacturing team optimizes PCB files for production while our global component sourcing from Arrow, Avnet, Future Electronics, Mouser and Digi-Key provides BOM alternatives and cost optimization.

Certified Quality

Our assembly operations follow IPC 610 Class 3 standards with UL certification, RoHS compliance, and lead free assembly processes for quality assurance.

Straightforward Pricing

Our quotes include detailed cost breakdowns for PCB fabrication, assembly, and components.

We validate BOM pricing upfront and hold quotes firm for the project duration without market adjustment surcharges.

Global Support

Our established partnerships handle duty optimization and delivery tracking for PCB assemblies and electronic products to global destinations.

Fast Lead Times

We accommodate urgent schedules through dedicated prototype production lines.

Materials We Use for One Stop PCB Assembly Manufacturing

We use eight main PCB materials including FR4, Rogers, aluminum, copper core, ceramic, flex PCB and rigid-flex substrates for one stop PCB assembly projects.

Each material type handles different application needs from standard consumer electronics through high frequency RF designs and extreme temperature environments.

| Material Type | Description & Applications | Specifications |

|---|---|---|

| FR4 Standard | The most commonly used material for PCB fabrication. FR4 provides reliable performance for general purpose electronic products and offers excellent cost effectiveness for standard applications. | Glass transition temperature: 266°F to 356°F (130 to 180°C). Operating range: negative 40°F to positive 266°F (-40°C to +130°C). Dielectric constant: 4.2 to 4.6 @ 1MHz. |

| High-Tg FR4 | High temperature FR4 variant designed for lead free assembly processes requiring higher thermal stability. High Tg materials prevent delamination during reflow processing and extend operating temperature ranges. | Glass transition temperature: 338°F to 356°F (170-180°C). Operating range: negative 67°F to positive 302°F (-55°C to +150°C). Decomposition temp: greater than 572°F (300°C). |

| Flex PCB (FPC) | Flexible printed circuit board materials enable bending and folding within compact spaces. Flex PCB substrates connect moving parts while maintaining electrical performance through repeated flex cycles. | Polyimide base: 0.5 to 4 mil thickness. Flex life: greater than 100,000 cycles. Operating range: negative 328°F to positive 500°F (-200°C to +260°C). |

| Aluminum PCB | Aluminum substrates provide superior heat dissipation compared to FR4 materials. Aluminum PCBs suit high power applications requiring rapid thermal management, particularly LED lighting and power electronics. | Thermal conductivity: 1.0 to 2.0 W/m·K. Operating range: negative 40°F to positive 302°F (-40°C to +150°C). Dielectric strength: greater than 3000V/mil |

| Rogers Materials | Rogers substrates deliver advanced electrical properties for high frequency applications. When precise dielectric constants and low loss characteristics are needed, Rogers materials provide the solution for professional RF engineering. | Dielectric constant: 2.2 to 10.2 ± 0.02. Frequency range: DC to 77 GHz. Loss tangent: 0.0009 to 0.0035. |

| Ceramic PCB | Ceramic substrates handle extreme temperature applications beyond organic material limits. Alumina and aluminum nitride ceramics provide exceptional thermal conductivity and dimensional stability for demanding environments. | Thermal conductivity: 24 to 30 W/m·K. Operating range: negative 452°F to positive 3092°F (-269°C to +1700°C). Dielectric constant: 9.8 @ 1MHz. |

| Rigid Flex PCB | Rigid flex combinations integrate FR4 rigid sections with polyimide flex areas in single PCB designs. These materials eliminate connectors while enabling three dimensional PCB configurations for compact electronic products. | Impedance tolerance: ±5 to 10%. Twist & warp: less than 0.75%. Temperature cycling: negative 67°F to positive 257°F (-55°C to +125°C). |

What Is One-Stop PCB Assembly?

One-stop PCB assembly is a manufacturing service where one vendor handles PCB fabrication, component sourcing, and assembly operations for complete electronic assemblies. Customers work with one service provider instead of coordinating between a separate PCB manufacturer, component distributor, and assembly factory suppliers.

This approach delivers cost savings through bulk purchasing, faster assembly production, and consistent quality control across all manufacturing stages. Electronic products requiring PCB assemblies achieve faster time-to-market through one stop PCB assembly workflows.

What to Consider for Your One Stop PCB Assembly Design

Component Placement

Group similar component types together to reduce machine setup time while placing tall components away from smaller parts to prevent shadows during reflow processing.

Provide adequate space around BGA components for X-ray inspection access and keep components away from PCB edges to prevent damage during handling.

Solder Pad Design and Stencil Considerations

Avoid oversized pads that can cause solder bridging during reflow while making pads large enough to support reliable solder joints.

Consider stencil aperture requirements when designing pad layouts and maintain consistent pad sizes across similar components for uniform solder paste volume.

Thermal Management and PCB Materials

Choose High Tg FR4 for lead free assembly processes, flex PCB materials for bending applications, or copper core substrates for high power requirements.

Test Point Access and Assembly Testing

Design optical inspection targets for automated AOI systems and plan component placement for X-ray inspection access on BGA components.

Via Placement and Signal Integrity

Use via-in-pad designs only when necessary due to additional fabrication costs while positioning vias to support thermal management without interfering with assembly.

Route high-speed signals away from noisy components and use proper impedance control for important signal paths.

BOM Management and Component Selection

Choose components during the design phase to prevent conflicts and maintain up-to-date BOM information for accurate component procurement throughout one stop PCB assembly projects.

Industries We Serve with One Stop PCB Assembly

Our one stop PCB assembly facilities manufacture electronic assemblies for automotive, medical, telecommunications, industrial, consumer and aerospace applications.

Each industry requires different temperature ranges, regulatory standards and reliability specifications that our PCBA manufacturing processes accommodate through specialized assembly protocols.

Automotive Electronics

Medical Devices

Telecommunications Infrastructure

Industrial Automation

Consumer Electronics

Aerospace Applications

How to Order Your One Stop PCB Assembly

Submit Your PCB Design

Upload your Gerber files or use our easy online PCB design tool to create your board layout. Make sure your files are complete and correctly formatted to ensure smooth processing and production accuracy.

Select Your PCB Specifications

Customize your order by choosing the technical specifications—number of layers, board dimensions, thickness, copper weight, solder mask color, surface finish, and more. Our intuitive interface helps you configure everything based on your project’s needs.

Get an Instant Quote

Once your design and specs are in place, you'll receive a transparent, instant quote. Pricing updates in real time as you modify options, so you can adjust your selections to match your budget before placing the order.

Confirm Order & Make Payment

Review your entire order for accuracy, including file previews and selected specs. After confirmation, proceed to secure checkout and choose your preferred payment method. You’ll receive an email confirmation with order details.

Production & Delivery

Your PCB moves into production immediately. We’ll keep you updated throughout the manufacturing process. Once completed, your boards are carefully packed and shipped to your door, with tracking information provided for your convenience.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB?

WellPCB stands out among USA PCB manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top PCB manufacturers in USA.

WellPCB specializes in multilayer PCBs for advanced electronic applications. You can order these boards with $100 off using our special offer, providing high complexity at competitive rates for demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

One Stop PCB Assembly Case Studies

PCB Assembly

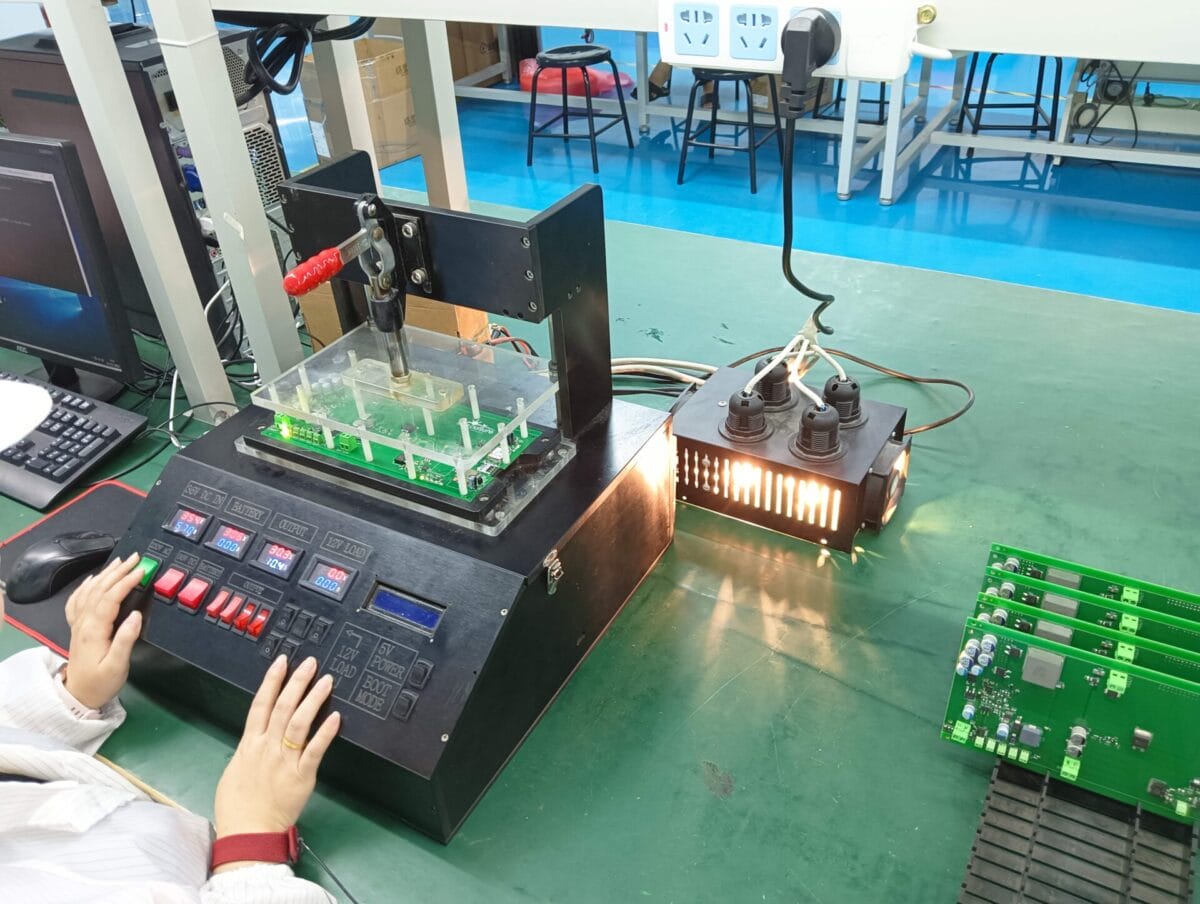

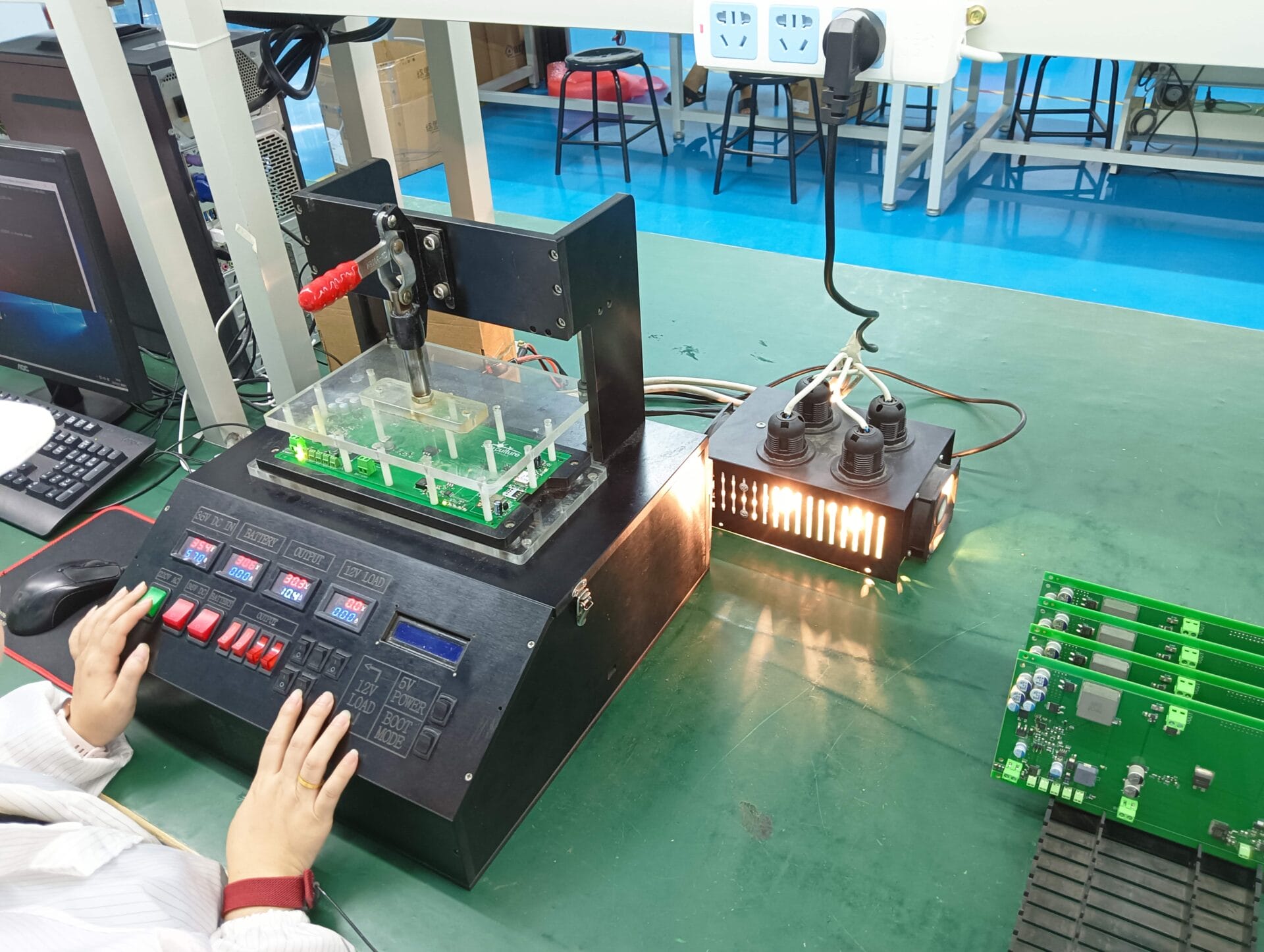

A worker is concentrating on operating professional testing equipment to program and test the circuit board.

Programming is to load software code into the microcontroller or programmable device on the PCB, so that it can control various components on the circuit board and achieve specific functions.

Testing is to check whether there are defects in the manufacturing process of the PCB board and ensure that its functions and performance meet the design requirements.

PCB Assembly

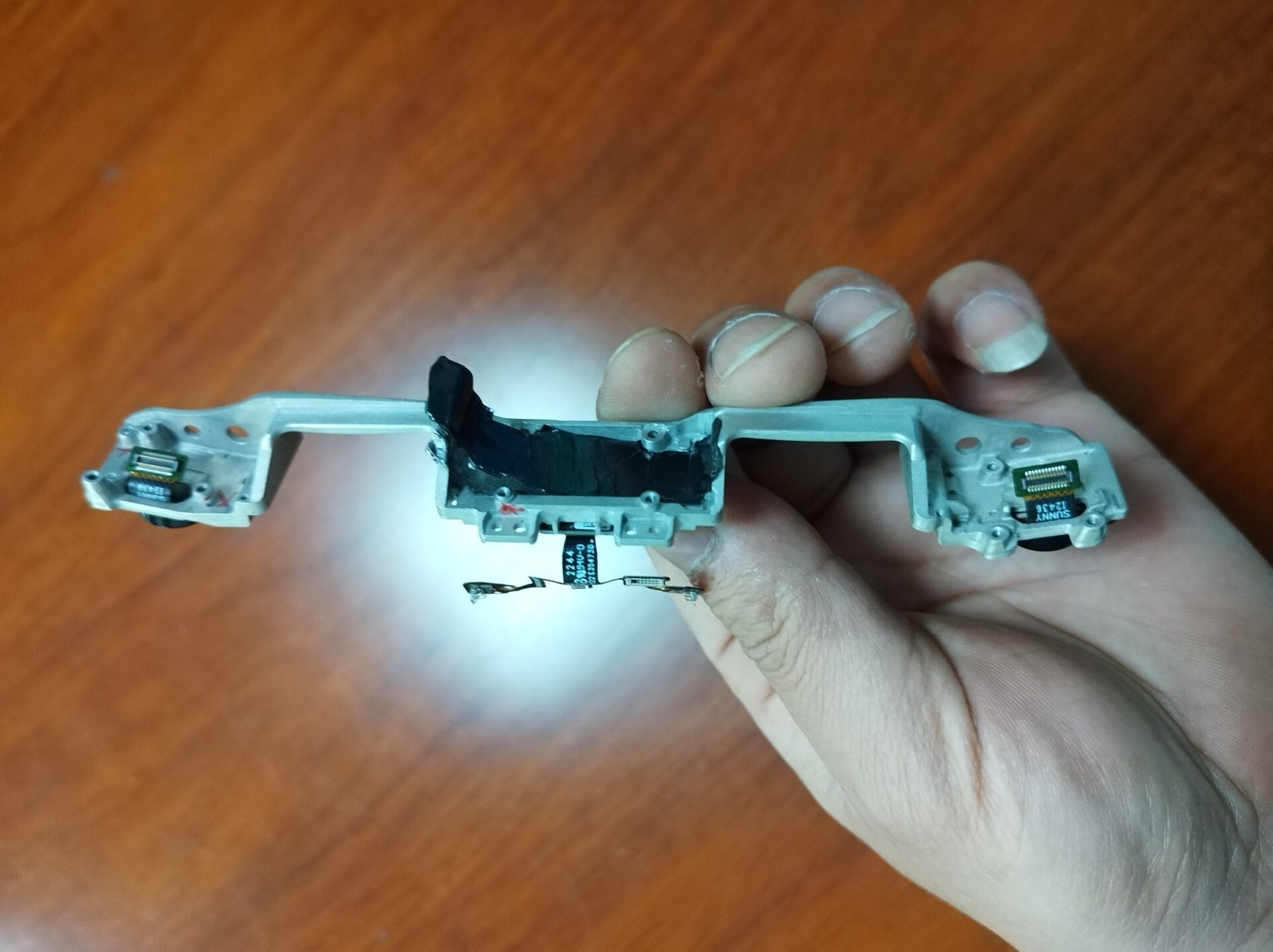

We can also do the Case printing and production, also an important part in One Stop PCB Assembly.

You can provide us with 3D files, and we will produce prototypes and batches according to the files.

Before developing the mold, the first prototype will be made to check the appearance and function.

PCB Assembly

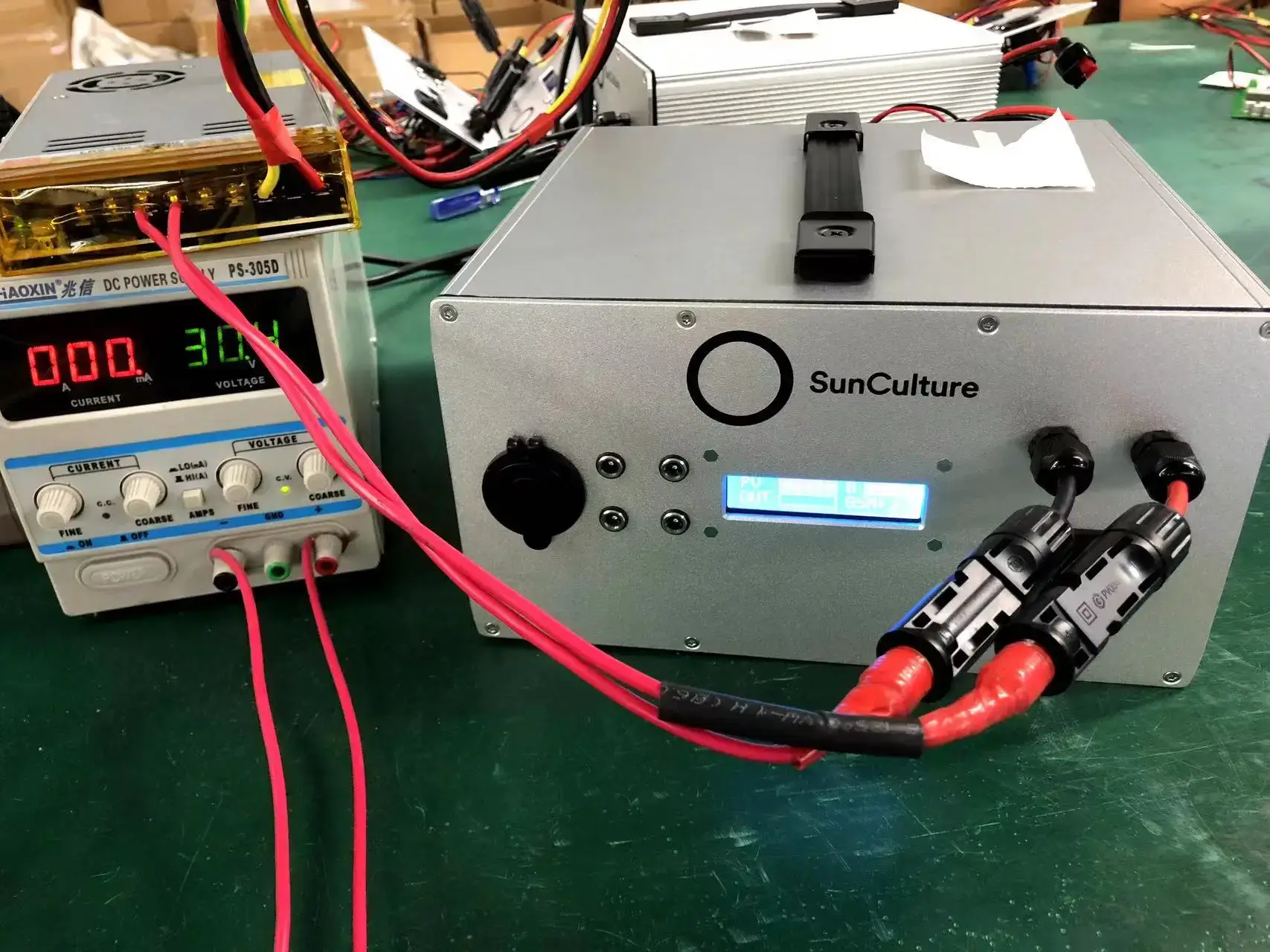

One-stop assembly services provide a complete product, simplifying the process for the customer.

We performs complete assembly and testing of the assembled boards, wiring harnesses, and cases.

One Stop PCB Assembly Client Feedback

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

One Stop PCB Assembly Services FAQs

How is quality control maintained throughout assembly?

Do you offer conformal coating applications?

Yes, conformal coating services are available as part of our box build assembly operations. We apply acrylic, urethane, and silicone coatings for moisture protection and environmental resistance. Coating application includes masking of connectors and test points per customer specifications.

Can you scale production for large volume orders?

How are sensitive components securely stored?

Sensitive electronic components receive ESD-safe storage in humidity and temperature-controlled environments. BOM tracking systems maintain component traceability while inventory rotation prevents aging issues.

Streamline Your Project with WellPCB’s One Stop PCB Assembly Services

Get $100 Off Your First Order!

From DFM checks to final assembly, we’ll help keep your project all under one roof and with cost savings too. Get a free quote now!