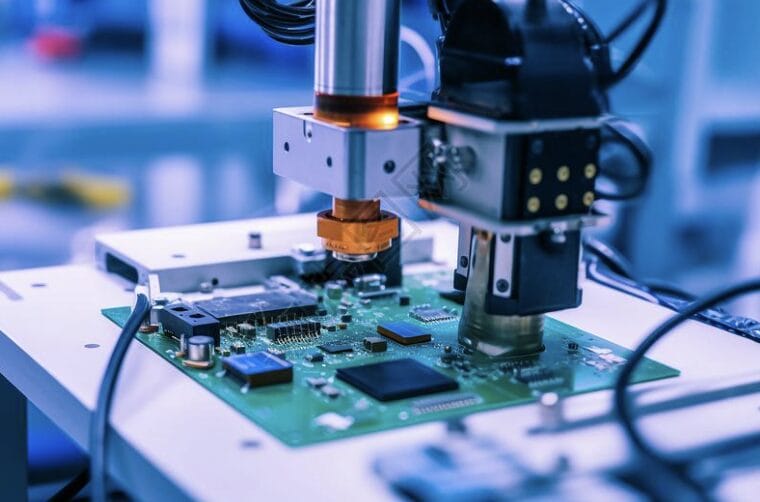

Precision Low Volume PCB Assembly

for Prototypes and Small Batch Builds

Low volume PCB assembly refers to the production of 1 to 250+ assembled boards for prototyping, custom electronics, and short-run product validation. WellPCB provides complete turnkey PCB assembly services that undergo automated optical inspection (AOI), X-ray inspection for hidden joints, and full visual inspection to ensure reliable performance.

- Small scale PCB manufacturing for 1 to 250+ units with no minimum quantity.

- Quick turnaround low volume PCB assembly services in 24 to 72 hours for prototype volumes when components are in stock and design files are production-ready.

- Full BOM sourcing, engineering review, and turnkey PCBA for complex prototypes.

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

- PCB Manufacturer

- PCB Assembly Service

- Low Volume

Precision PCB Assembly for

Low Volume Production Needs

Low volume PCB assembly supports functional prototyping, limited production runs, and early market testing without the cost burden of high-volume tooling.

Our small batch PCB assembly process is built for flexibility, allowing rapid design iteration, low-cost changes, and fine-tuned solder quality even on short production cycles. Whether you need 5 units or 200, every printed circuit board is assembled to IPC standards with traceability and testability built in.

We specialize in complex circuit builds that use double-sided SMT, through-hole components, or custom mounting requirements. Our technical capabilities are backed by IPC-A-610 Class 2 and Class 3 standards, supporting SMT, PTH, and mixed technology assembly with fine-pitch BGA placement down to 0.2 mm and QFPs with 0.15 mm lead width.

Our low volume PCB assembly lines operate in ISO 9001-certified manufacturing facilities with real-time process control, advanced soldering systems, and DFM/DFT checking on all builds. Our engineers review every BOM and Gerber file set before manufacture, applying strict DFM checking to optimize yield, reduce errors, and flag potential issues early. This results in faster board manufacturing, fewer revisions, and consistent assembly quality regardless of quantity.

Our Low Volume PCB Assembly Capabilities

WellPCB delivers precision-driven small volume PCB assembly using fully automated SMT lines, optical inspection systems, and verified engineering workflows. From 1-piece functional prototypes to 250-unit pre-production batches, every printed circuit board is assembled in an ISO-certified factory with advanced surface mount, through-hole, and mixed technology support.

We support low volume PCB assembly for builds ranging from 1 to 250+ units, with scalable support up to 5,000+.

The placer speed is 60,000 chips per hour. The assembly accuracy is ±30 μm under the condition of 3σ, and CPK ≥1.

This service is designed for engineering validation, test runs, and limited product launches where speed and solder quality are key.

| Parameter | Value / Range |

|---|---|

| Supported Order Quantity | 1 to 250 units (Scalable to 5,000+ units) |

| Supported Package Types | 0201, QFN, BGA, CSP, PoP, Fine-Pitch ICs |

| Equipment Used | 8 YAMAHA + 5 Siemens SMT lines across two facilities |

| Accuracy | <±30μm, under the condition of 3σ,CPK≥1 |

| Board Thickness Range | 0.5 mm to 4.5 mm |

| Max Board Size | 610 mm × 508 mm |

| Turnaround Time | 24 to 72 hours (prototype quantities) |

Our assembly lines support surface mount technology (SMT) with 0201 packages and BGA components down to 0.2 mm pitch.

We also provide plated through-hole (PTH) and mixed mounting techniques on single or double-sided PCBs.

Dual reflow soldering profiles are used for two-sided assemblies, with adhesive stabilization and test points preserved.

WellPCB offers turnkey PCB assembly services for low volume builds using Digi-Key, Mouser, and Element14 for fast sourcing.

We support BOMs with parametric substitutes, RoHS-compliant components, and just-in-time availability. All sourcing steps are traceable and fully documented before PCB production.

We accept Gerber RS-274X/274D, pick-and-place files, DXF, DWG, and Excel BOMs.

Every small batch PCB assembly order undergoes DFM checking for solder mask accuracy, pad spacing, and silkscreen conflicts.

Engineering support includes feedback on drill hits, board outline tolerances, and solder joint clearance.

Supported solder types include lead-free, HMP, and Au80 solder for temperature-sensitive builds.

Selective wave soldering is used on PTH boards, with nitrogen-controlled reflow for precision SMT. All soldering processes comply with RoHS, REACH, and IPC-A-610 Class 2 or 3.

Automated optical inspection (AOI) is used on all builds. X-ray inspection validates BGA and CSP joints, and flying probe tests verify electrical continuity for low quantity runs.

DFT services optimize test point layout, while functional test jigs are supported upon request.

Boards up to 610 mm × 508 mm are supported with thicknesses from 0.5 mm to 4.5 mm. We assemble rigid, flexible, and rigid-flex PCBs with custom panelization, edge plating, and partial stencil printing.

Each line can adapt to product-specific requirements, including real-time file updates or partial re-runs.

All files are reviewed by PCB assembly engineers prior to production. Real-time quoting allows immediate cost feedback for low volume PCB assemblies, with DFM and DFT checks completed before final approval.

Engineering feedback includes trace isolation, test access, and panel fiducial alignment.

Our assemblies follow IPC-A-610H, the current industry benchmark for electronic assembly acceptability.

We support Class 1 (general electronics), Class 2 (dedicated service), and Class 3 (high-reliability) builds. Inspection criteria are based on solder joint integrity, component placement accuracy, and cleanliness standards defined in this framework.

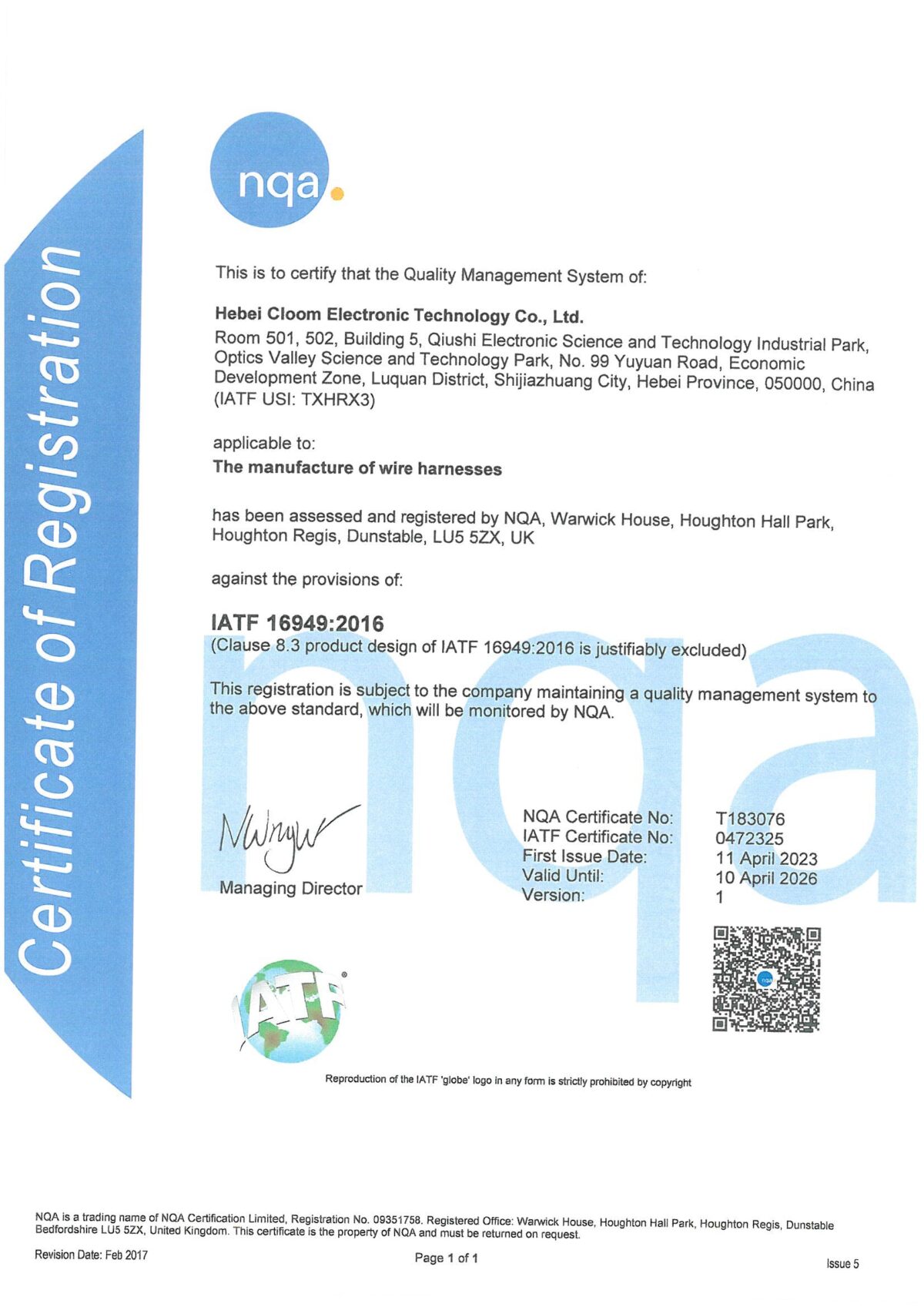

Our low volume PCB assemblies comply with RoHS and REACH environmental directives, and we maintain alignment with IATF 16949 standards for automotive PCB quality management where applicable.

Why Choose WellPCB for Your Low Volume PCB Assembly?

Our processes align with guidelines from the IPC (Association Connecting Electronics Industries) and are developed using principles promoted by the SMTA (Surface Mount Technology Association), ensuring traceable and standardized build quality.

No MOQ for Low Volume PCB Assembly

Fast Turnaround with Real-Time Quoting

With manufacturing facilities optimized for small batch PCB assembly, we deliver prototypes in as little as 24 hours.

Our instant online quoting tool provides real-time cost estimates for BOMs, Gerber files, and PCB assembly services to meet your delivery schedule and engineering budget.

Advanced Manufacturing Facilities and SMT Lines

Full DFM and DFT Checking Included

Turnkey PCB Assembly with BOM Flexibility

Certified Quality and Traceable Results

What is Low Volume PCB Assembly?

Low volume PCB assembly typically covers builds ranging from 5 to 5,000 assembled units. At WellPCB, we specialize in 1 to 250-unit runs but offer scalable support up to 5,000+ for qualified small batch production needs. This category supports small batch PCB assembly for prototypes, regulatory submissions, and pilot production, with no minimum order quantity. Unlike high-volume production, the process is optimized for fast changeovers, DFM-driven adjustments, and high-precision soldering across low unit counts.

WellPCB’s low volume PCB assembly services support multilayer board configurations up to 64 layers, using controlled impedance stackups, blind and buried vias, and minimum trace widths down to 1.8 mil.

We accept Gerber files in RS-274X or 274D format and BOMs in CSV or Excel, performing full DFM and DFT checking before panelization. Supported board thicknesses range from 0.5 mm to 4.5 mm, with surface finish options including ENIG, OSP, immersion silver, and lead-free HASL.

Assemblies are built on automated SMT lines with placement precision of ±30 μm (3σ) and include AOI, X-ray inspection, and optional functional testing. Components down to 0201, BGA with 0.2 mm pitch, and CSPs are supported.

All low volume PCB assemblies are manufactured in ISO 9001-certified facilities to IPC-A-610 Class 2 or Class 3 standards, enabling rapid iteration with guaranteed solder joint integrity and traceable quality control.

What's the Difference Between Low Volume and High Volume

PCB Assembly?

| Specification | Low Volume PCB Assembly | High Volume PCB Assembly |

|---|---|---|

| Typical Build Range | 1 to 250 units (scalable to 5,000) | 5,000 to 1,000,000+ units |

| Turnaround Time | 24 to 72 hours (prototypes), 5 to 7 days (standard) | 2 to 4 weeks standard with locked scheduling |

| Design Iteration Flexibility | High – supports ECOs, redesign, test point rework | Low – requires finalized, frozen design files |

| Cost Structure | Higher per-unit due to setup/tooling amortization | Lower per-unit through volume efficiency and automation |

| DFM/DFT Review | Included for every build (Gerber, BOM, stencil, panel) | One-time review for initial NPI, reused across batches |

| Testing Protocols | AOI, X-ray, flying probe, functional test per board optional | Statistical testing or AQL sampling on selected boards |

| Component Sourcing | Just-in-time, Digi-Key, Mouser, Element14 sourcing | Contract-based bulk procurement through authorized distros |

| Assembly Line Configuration | Modular lines for quick changeover and hybrid builds | High-throughput SMT lines with minimal variation |

| Industries Served | Prototyping, aerospace, automotive, medical, R&D | Consumer electronics, industrial, telecom, computing |

Industries We Serve with Low Volume PCB Assembly

Low volume PCB assembly is widely used across industries that demand fast prototyping, regulatory validation, and complex circuit builds without committing to full-scale production. We support highly specific requirements with full DFM/DFT review, solder traceability, and consistent quality across all low volume PCB assemblies.

Medical Electronics

We manufacture small quantity PCB assemblies for wearable monitors, clinical diagnostic devices, and implantable electronics.

Builds meet IPC Class 3 requirements with lead-free solder, fine-pitch SMT, and board-level functional test validation.

Aerospace and Defense

WellPCB supports aerospace PCBs with blind vias, via-in-pad, and high-Tg materials designed for high-temperature cycling and vibration tolerance.

All circuit boards undergo x-ray inspection and conform to strict trace width and spacing tolerances.

Automotive Prototyping

Our low volume PCB assembly services support ECU test modules, sensor hubs, and driver-assist prototypes.

We offer custom PCB stackups for power delivery, thermal performance, and CAN signal integrity across double-sided boards.

Consumer Electronics Startups

Startups building wearables, smart devices, or IoT platforms rely on our low volume PCB assemblies for rapid validation and user testing.

We handle small batch PCB assembly with flexible sourcing, real-time file updates, and on-demand rework.

Industrial Control Systems

We support low volume assembly for machine control boards, HMI interfaces, and predictive maintenance systems.

Our facilities process complex BOMs with mounting of relays, sensors, and high-current connectors alongside fine-pitch ICs.

Academic and Research Institutions

Universities, R&D labs, and student teams use our small scale PCB manufacturing services for test rigs, robotic subsystems, and embedded electronics.

We provide instant online quoting, engineering feedback, and delivery under one week.

Our Low Volume Assembly Process

in 5 Easy Steps

Submit Your PCB Design

Upload your Gerber files or use our easy online PCB design tool to create your board layout. Make sure your files are complete and correctly formatted to ensure smooth processing and production accuracy.

Select Your PCB Specifications

Customize your order by choosing the technical specifications—number of layers, board dimensions, thickness, copper weight, solder mask color, surface finish, and more. Our intuitive interface helps you configure everything based on your project’s needs.

Get an Instant Quote

Once your design and specs are in place, you'll receive a transparent, instant quote. Pricing updates in real time as you modify options, so you can adjust your selections to match your budget before placing the order.

Confirm Order & Make Payment

Review your entire order for accuracy, including file previews and selected specs. After confirmation, proceed to secure checkout and choose your preferred payment method. You’ll receive an email confirmation with order details.

Production & Delivery

Your PCB moves into production immediately. We’ll keep you updated throughout the manufacturing process. Once completed, your boards are carefully packed and shipped to your door, with tracking information provided for your convenience.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB?

WellPCB stands out among USA PCB manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top PCB manufacturers in USA.

WellPCB specializes in multilayer PCBs for advanced electronic applications. You can order these boards with $100 off using our special offer, providing high complexity at competitive rates for demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

Low Volume PCB Assembly Case Studies

PCB Manufacturing

An electronics client needed a high-density 8-layer PCB with tight design constraints. We delivered high-performance, reliable boards meeting strict electrical and structural requirements.

PCB Specifications:

- Layers: 8

- Board Thickness: 1.8mm

- Min. Line Width/Space: 3/3.5 mil

- Min. Hole Size: 0.2mm

- Min. Distance from Hole to Line: 0.13mm

- Inner Layer Copper: Hoz

- Outer Layer Copper: 1oz

- Surface Finish: Immersion Gold

The final board met all mechanical and electrical tolerances and passed electrical testing with 100% yield. This project shows our capabilities to handle complex, high-density multilayer PCBs with tight tolerances and strict quality standards.

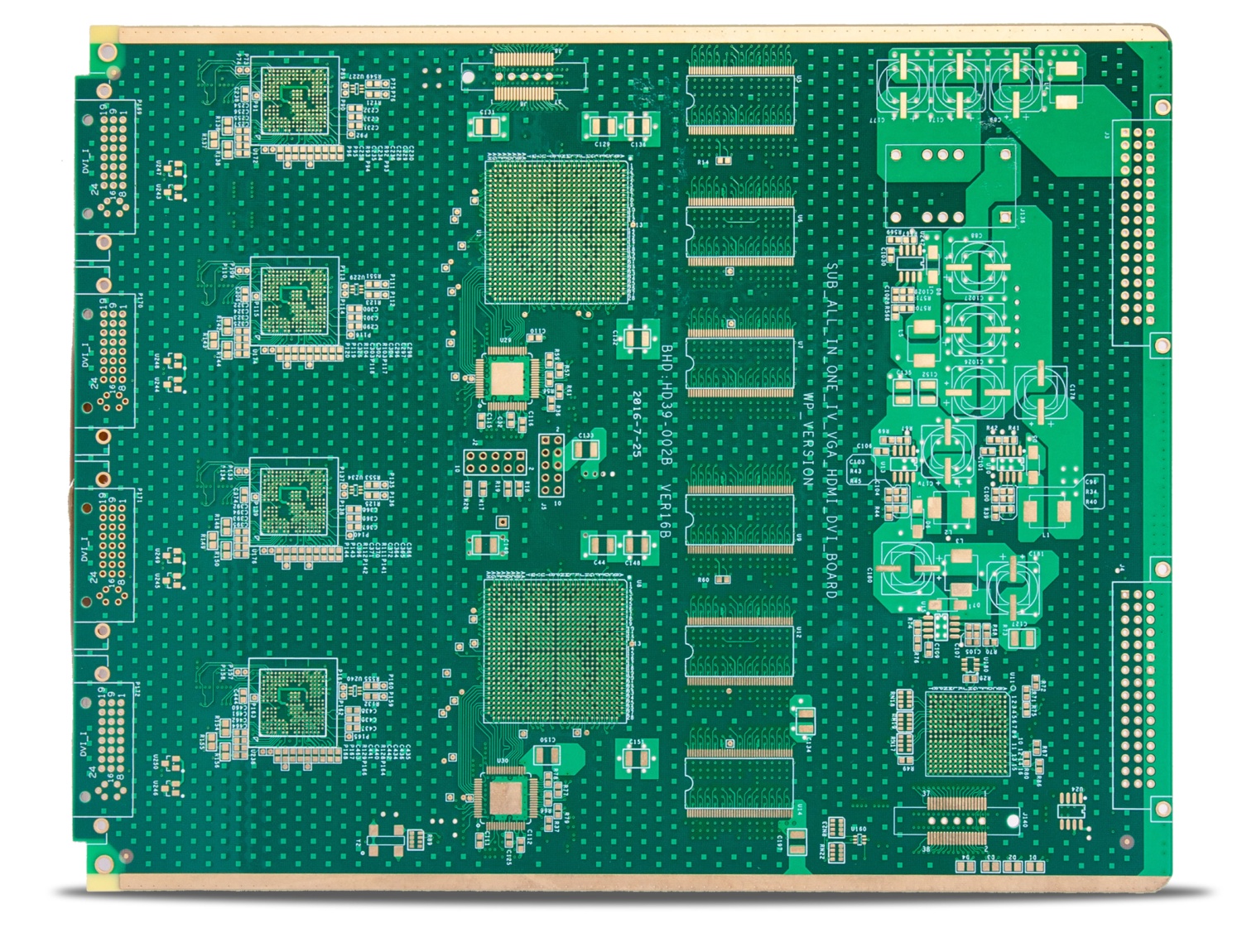

PCB Assembly

A PCB design firm in Italy required short-run production of a complex board with both SMT and THT components. We managed the full assembly process, including component sourcing, PCB manufacturing and assembly, inspection, and shipping.

Project Details

- Service Type: PCB Assembly

- Location: Italy

- Client Type: PCB Design Company

- Total Units: 20

- Lead Time: Rapid turnaround for prototyping

- Assembly Type: SMT+THT mixture assembly

Our experienced production team worked closely with the client to verify the BOM, optimize the stencil and the board’s layout design. We completed and delivered 20 fully assembled units within the expected lead time, allowing the client to avoid delays and meet their customers’ delivery window. This case highlights our capabilities to support global clients with flexible, low-volume PCB assembly solutions.

PCB Assembly

This PCBA solution integrates a custom PCB with high-precision SMT assembly, tailored specifically for smart fingerprint lock systems. Designed for household appliances, it combines compact size, low power consumption, and reliable signal processing to support biometric recognition and secure user access.

Technical Specifications:

- Product Type: PCBA (PCB + SMT Patch)

- Application Product: Smart Fingerprint Lock

- Industry/Application: Home Appliances / Smart Home

- Assembly Process: Surface Mount Technology (SMT)+THT

- Function: Biometric signal processing, control logic

Client Feedback On Our Low Volume PCB Assembly

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

Low Volume PCB Assembly FAQs

What is your minimum order quantity for PCB assembly?

We support low volume PCB assembly starting from just 1 unit. This allows for fast iteration during prototyping and small batch PCB assembly runs for validation, pilot testing, or market sampling.

What file types do you accept for small-scale PCB manufacturing?

We accept Gerber RS-274X and RS-274D files for PCB fabrication, BOMs in Excel or CSV, pick-and-place files in ASCII/CAD formats, and mechanical drawings in DXF or DWG. All files are reviewed through DFM checking before board manufacturing begins.

Can you assemble boards with fine-pitch BGA and mixed technology?

Yes, our assembly lines support BGA, uBGA, QFN, CSP, and through-hole components in mixed mounting configurations. BGA pitch down to 0.2 mm and double-sided SMT are supported even for low volume PCB assemblies.

What types of testing do you offer for small batch PCB assembly?

All PCB assemblies undergo AOI and visual inspection by default. X-ray inspection is used for BGA and hidden-joint verification. Flying probe test (FPT) and functional testing are available on request, depending on the circuit’s test point accessibility.

Are your low-volume PCB assembly services RoHS compliant?

Yes, we offer RoHS-compliant soldering using lead-free SAC alloys and maintain traceability for all solder batches. Conformal coating, HMP soldering, and Au80 options are also available for assemblies with specific environmental or thermal requirements.

Get $100 Off Your First Low Volume PCB Assembly Order

Whether you’re building a prototype, testing a new concept, or preparing a short-run production launch, our low volume PCB assembly services deliver speed, accuracy, and engineering flexibility. Submit your Gerber files and BOM today to receive a real-time quote and dedicated support from our assembly engineering team.