Custom Industrial Cable Assembly Made to Last in Harsh Environments

Custom industrial cables outperform standard cables because they’re built to last long term in tough conditions.

Your needs determine the features of your custom cables. That includes voltage ratings, shielding levels, jacketing materials, bend radius and how much heat the cable can handle.

WellPCB manufactures custom industrial cables for industrial automation, OEM machinery, medical equipment, and fiber optic systems.

These fully custom cables come with high performance copper or hybrid conductors, polymer insulation and shielding to block signal noise and withstand wear.

All assemblies meet IPC/WHMA-A-620 Class 3 standards for mission-critical environments where reliability is not an option.

- Custom cable assemblies for factory systems, robots, medical devices, and automotive equipment

- Copper cables with XLPE or PVC insulation and full foil-braid shielding

- No minimum order quantity for one-off prototypes or full production runs

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

Custom Industrial Cable Assemblies for Demanding Applications

Custom industrial cables and wiring harness carry power, signal and data between different types of machines. They’re used in almost every industrial environment for their reliability.

We build our cable assemblies to perform trouble free under high loads, vibration and EMI. Exact specifications depend on the routing, shielding and jacket requirements for the application the cable will be used in. No extra length or unnecessary features included.

Our technicians use materials like copper cable, XLPE insulation and foil-braiding shielding so each cable will withstand temperature swings and mechanical pressure.

Looking for a custom industrial cable manufacturer you can trust? WellPCB checks all the boxes. Our products run machines in the automation, medical, automotive and aerospace industries, proving their strength and performance. Every cable comes with test data to prove it’s been tested for real world use.

Our Industrial Cable Manufacturing Capabilities

WellPCB makes every industrial cable and industrial cable assembly from your technical drawings, samples or specifications. Our manufacturing process is controlled to meet all mechanical, electrical and dimensional requirements, and we can provide full traceability to prove it.

We support low voltage power cables (12V to 48V), multicore signal cables, LVDS interconnects, micro coax, and hybrid round-to-FFC lines.

Depending on layout and insulation type, we can handle conductor counts from 2 to 64 and OD sizing from 2.5 mm to 18 mm.

Every material in your custom industrial cables is sourced to your specs. We offer a choice of Class 5 or 6 flexible stranded copper cable conductors.

Our XPLE insulation is -40 °F to 257 °F (-40 °C to 125 °C). PVC options are -14 °F to 194 °F (-10 °C to 90 °C).

If you choose a halogen free jacket, each one meets UL VW-1 and IEC 60332-3-24 flammability ratings. They’re also tested for Shore A hardness per ASTM D2240.

Your cable’s shielding configuration can be 100% aluminum foil, 90 to 96% tinned copper braid, or a hybrid of both.

If you’re ordering a triaxial or fiber optic cable, we can add steel braid or drain wire structures.

All shielding is tested to <5 mΩ loop resistance and ≥90 dB attenuation across 10 MHz to 1 GHz to make sure they can handle EMI.

We can source any connector you prefer including ACES, JST, DF9, IPEX and open flying leads. Crimping, soldering and IDC application depends on your spec.

Once built, we’ll verify them against your original pin map using multichannel continuity testing. Our processes follow IPC-A-620 Class 3 visual and mechanical inspection rules.

We do full-length inkjet jacket printing, heat-shrink tags, serial markings, and barcoded sleeves.

All custom wire and cable markings meet UL (≤24 in intervals) and ANSI/EIA-455-95A abrasion requirements.

If you want part-level tracking or brand-specific identifiers, let us know upfront, and we’ll arrange it.

To add abrasion, impact and tension protection we offer Kevlar overbraid (1500 to 3500 denier), flame-barrier sleeving (UL rated) and corrugated steel armor with ≥1,000 lb/in² radial strength.

Once applied, we’ll test the cable to ensure it meets pull-force thresholds and bend radius (minimum 5× OD) as specified in your spec.

We test milliohm resistance, continuity and dielectric to withstand (1500 VDC at ≤1 mA leakage).

For high frequency cable assemblies, we use TDR (rise time <250 ps). We also do flex cycle, crush and tensile testing.

If you want the test results included with your delivery, we can send you job records with your custom industrial cables.

We handle prototype quantities (as low as 5 units) and mass production up to 50,000 or more units.

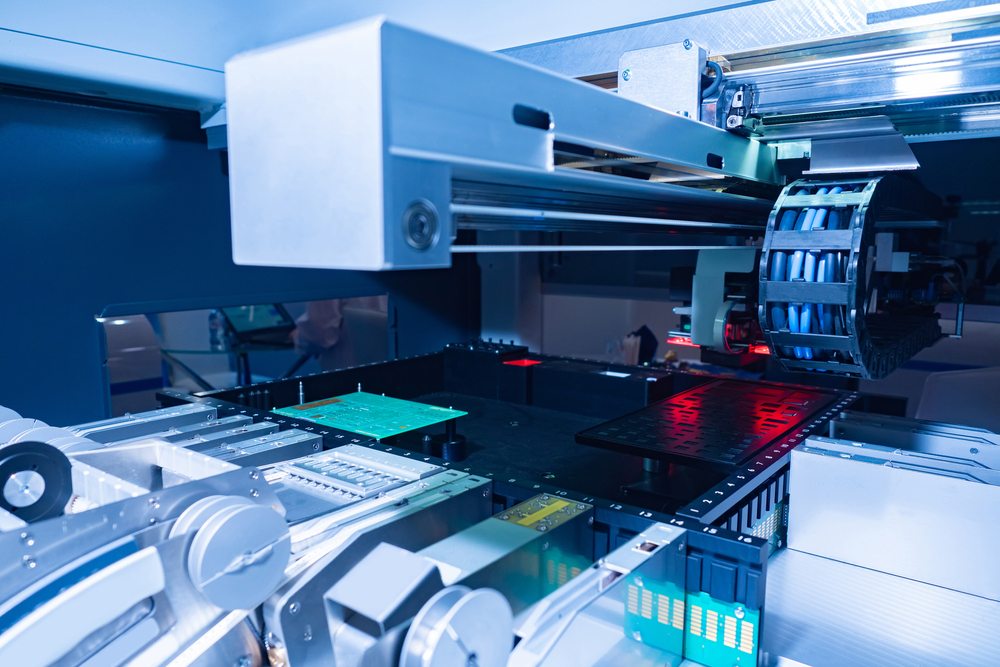

As a high-capacity industrial cable manufacturer, our production process uses automated jacket preparation, cutting, stripping, and crimping machines, and inline verification tools.

We keep dimensional tolerances to IPC requirements, with serialized job tracking throughout all manufacturing processes.

Why Choose WellPCB as Your

Industrial Cable Manufacturer?

Clients trust us for our high-quality custom industrial cable production, which includes fixed tolerances and easy traceability of the entire production and testing process. Our technicians track every step of the process to help us maintain our high standard, no matter if the order is 5 or 50,000+ units.

Build-to-Spec Cable Execution

Certified Quality Standards

Flexible Production Runs

Advanced Manufacturing Processes

System-Level Integration Support

We provide BOM verification, pin mapping, and connector breakout prep to make installing your cables easier.

Dedicated Manufacturing Support

Industries that Use Our Custom Industrial Cables Solutions

WellPCB supplies clients with custom industrial cables for their specific needs. We make each one to perform even in demanding installations, by carefully manufacturing it to match the insulation, shielding, and certification needs of its use case.

Factory Automation & Robotics

Heavy Equipment & Power Systems

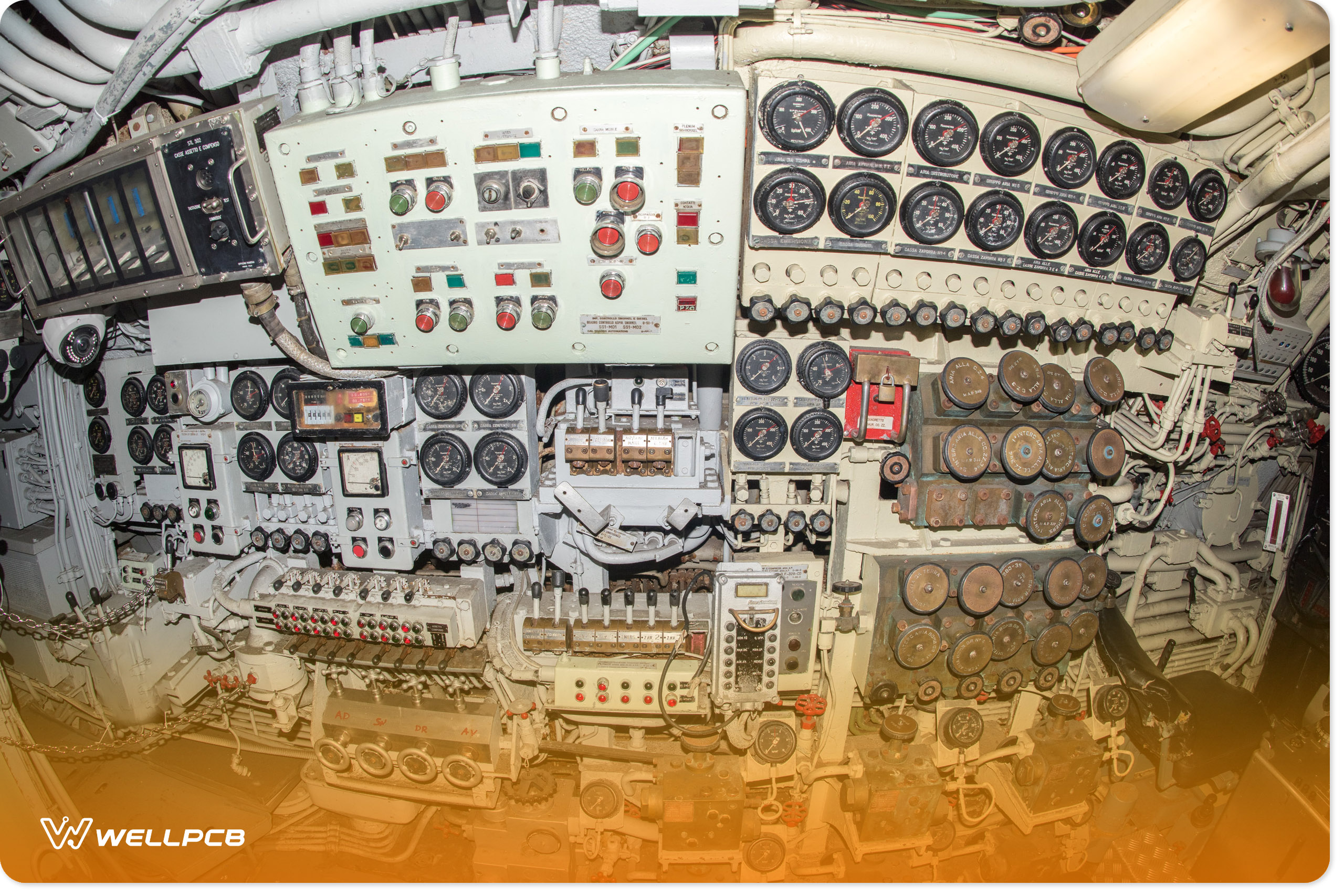

Marine and Offshore Systems

Automotive & EV Charging Infrastructure

Medical Manufacturing & Cleanroom

Renewable Energy & Utilities

Our Process for Custom Industrial Cable Manufacturing

WellPCB’s production workflow is carefully structured so we get perfect products every time. With your supplied specifications and our job-specific checkpoints, we’re able to maintain excellent outputs no matter how big your order or what parts you need.

Specification & Application Review

Material and Connector Matching

Prototype Build and Sampling

Production and Final Testing

Packaging and Shipment

What are the Design Considerations for Custom Industrial Cables?

Stripping behavior, connector fit, and jacket hardness directly affect production time. Your design choices also shape how the cable performs during installation and long-term use.

Electrical Parameters

Mechanical and Environmental Needs

Shielding and EMI Control

Labeling and System Integration

Submit Your Design

Send us your design details (Drawing or Detailed Specifications).

Get a Fast Quote

Once your design and specs are received, a fast quote will be sent to you within 24 hours.

Confirm Order & Make Payment

When the quotation is approved, please send the PO or order confirmation, we will proceed with the production after receiving your payment.

Arrange Production & Inspection

Before production, our technical team will review all details of the drawing/specs again. If everything is OK, the order will start. We'll keep you updated throughout the manufacturing process. After the production is completed, the products will be 100% inspected.

Packaging & Delivery

When completed, your order will be carefully packed and shipped to you, with shipping documents and tracking information provided.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB as Your Wire Harness Manufacturer?

WellPCB stands out among USA wire harness manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top wire harness manufacturers in the USA.

WellPCB specializes in custom wire harnesses for complex electronic and industrial applications. You can order these assemblies with $100 off using our special offer—delivering high-quality, tailor-made harnesses at competitive rates for your most demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

Wire Harness

This cable is commonly used in industrial machinery.

Customers need to select the appropriate wire specifications (e.g. AWG) to ensure safe and reliable power transmission; select the appropriate wire length according to actual needs.

It is also important that the selected wire can withstand the rated voltage and current of the equipment.

Specifications:

- •Connector Type: IEC C13, C14, C15, C19, etc.

- •Voltage Rating: 250V AC

- •Current Rating: 10A / 16A

- •Cable Type: H05VV-F, H07RN-F, or custom

- •Switch Type: Rocker or toggle (inline or panel mount)

- •Temp Range: -25°C to +70°C

- •Jacket Material: PVC or rubber (flame-retardant)

- •Certifications: IEC 60320, VDE, UL, RoHS

Wire Harness

Switch box wires are essential for industrial automation, enabling safe and reliable control signal and power transmission in control panels, machinery, and factory systems.

Specifications:

- •Control various mechanical equipment

- •Cooperate with environmental control systems

- •Prevent electric shock, short circuit and fire, etc.

Wire Harness

Used to connect and control various sensors, actuators, robots, controllers and other equipment to achieve automated production and processes.

Specifications:

- •Voltage Rating: Up to 600V

- •Conductor: Stranded copper

- •Insulation: PVC, XLPE, or Teflon

- •Temp Range: -40°C to +125°C

- •Sheathing: Braided, spiral wrap, or corrugated conduit

- •Connectors: Circular, rectangular, DIN, or custom

- •Compliance: UL, CSA, ISO 9001, RoHS

Custom Industrial Cables Client Feedback

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

Custom Industrial Cables Manufacturer FAQs

What are industrial cables?

Industrial cables are electrical products used to distribute power, data, or control signals between machines or systems. Manufacturers create these cables for high reliability in environments with temperature changes, high levels of vibration, mechanical stress, or electromagnetic interference (EMI).

What are custom industrial cables used for?

Manufacturers recommend custom industrial cables when standard cables won’t be good enough for harsh conditions. Products in the automotive, robotics, energy, and medical industries need extra strength.

Why choose a custom industrial cable over a standard one?

Custom cables meet the exact performance and installation specs you need, so they include everything you need and nothing you don’t. This improves fit and function, and also reduces failure rates over time.

How do you handle component obsolescence for long-life custom cables?

Our technicians constantly monitor the availability of connectors, jackets, and wire and cable material. If any component becomes unavailable, we’ll provide a backward-compatible match with validation data.

Do you offer custom cables with integrated active or smart features?

We don’t stock cables with these features or help you design cables with these features. We can, however, build custom industrial cables with these features, as long as the active components are supplied by the customer.

Reliable Custom Industrial Cables Manufacturer with IPC/WHMA-A-620 Certification

Get $100 Off Your First Order!

WellPCB delivers custom industrial cables that handle your exact voltage, shielding, and environmental requirements. Your order includes IPC/WHMA-A-620 Class 3 certification, full traceability, and flexible production from 5 prototypes to 50,000+ units.