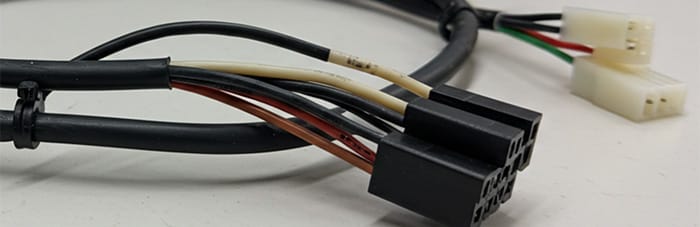

Precision-Built Control Cable Assembly Solutions

Our control cable assembly services deliver reliable motion transmission and electrical signal control for demanding environments.

With robust conduit options, precision end fittings and compliance with IPC/WHMA-A-620 Class 3, WellPCB supports applications across machinery in various industries.

- Stranded or solid wire core construction with low-friction PTFE liners

- Crimp force testing up to 1,000 N and insulation resistance to 600 V

- EMI-shielded conduit with overmolded strain relief for IP-rated sealing

ISO9001 ISO13485

ISO14001

IATF

16949

IPC-A-610H International

Certification

Fully Automated

AOI Inspection

What are Control Cable Assemblies?

Control cable assemblies are mechanical or electrical transmission systems that link an operator’s input to a controlled mechanism (like a throttle, valve, brake or actuator).

Each control cable assembly consists of a flexible wire or cable core, an outer conduit or casing and precise end fittings to convert motion or signals with minimal backlash and friction.

WellPCB produces high-performance control cable assemblies engineered for motion transmission in harsh, high-vibration environments. These assemblies support both mechanical actuation and electrical signal transfer, depending on the application. Our offerings include custom push pull cables, push pull control cables and remote control linkages, all tested for tensile strength, environmental durability and compliance with IPC/WHMA-A-620 Class 3.

Our Control Cable Assembly Capabilities

Our engineering team reviews every control cable assembly design for manufacturability, verifying cable routing paths, termination types and material compatibility.

We build custom control cables using high-performance wire cores paired with low-friction PTFE or nylon liners and ruggedized conduit jackets.

Cable jackets can handle cold from -40 °C to the heat of +105 ° C. They’re also manufactured to resist abrasion, oil and chemical exposure. Cablecraft-compatible components and MIL-SPEC-rated materials are available.

We manufacture each control cable assembly using automated cut-and-strip equipment, precision crimp presses and overmolding stations. Our crimp processes support terminals and connectors with tight dimensional tolerances.

For mechanical push pull control cable systems, we support solid or stranded wire rope cores with pre-load tensioning and casing compression calibration to maintain motion fidelity and reduce backlash in actuation mechanisms.

We supply a wide range of end fittings including clevises, ball-ends, threaded plugs, rod-end joints and bulkhead clamps. Thread sizes range from M3 to M12, and components are available in corrosion-resistant nickel, stainless steel or zinc-plated finishes.

Where signal transmission is required, control cable assemblies are manufactured with aluminum foil or braided copper shielding to mitigate EMI.

For mechanical systems, overmolded boots, sealed conduit interfaces and flexible strain reliefs provide ingress protection. Chemical and UV resistance are achieved with sheath materials tested to automotive and industrial standards.

Each control cable undergoes pull-force testing (up to 1,000 N), continuity testing and Hi-Pot voltage testing (up to 600 V) where applicable.

We use Cirris systems for electrical verification and digital pull testers for mechanical integrity. Every assembly is visually inspected for terminal seating, jacket integrity and casing defects prior to shipment.

We manufacture all control cable assemblies in ISO 9001 and IATF 16949 certified facilities.

Our materials and production processes meet RoHS and REACH directives, and we maintain UL traceability for common wire styles (1061, 1007, 1569, 1015).

We support build-to-print production volumes from single-piece prototyping to thousands of cable assemblies. Our flexible line setups allow for batch production with quick tooling changes and repeatable cable design adjustments.

The usual lead time for prototype orders is between 2 and 3 weeks. Standard production cycles range from 4 to 5 weeks, depending on the component mix and custom push pull cable complexity.

All control cable assemblies come with serialization, build history and electrical/mechanical test records. Labeling includes part number, revision level, operator ID and date code.

We maintain digital logs for each assembly, enabling full traceability from incoming material to final hardware shipment.

Why Choose WellPCB for Your Control Cable Assembly?

Build-to-Spec Control Cable Assemblies

We manufacture control cable assemblies to exact customer specifications, including casing type, wire gauge, end fitting geometry and preloaded cable tension. No off-the-shelf shortcuts.

IPC/WHMA-A-620 Class 3 Production

Accelerated Prototyping with Global Delivery

We produce functional prototypes within 2 to 3 weeks and ship globally. Our streamlined quoting and approval process reduces your development time from the usual 8 to 12 weeks offered by other manufacturers.

Fully Traceable Cable Parts and Materials

Multi-Industry Engineering Insight

We support cable assemblies across a range of applications. Our production teams understand how to customize cables to fit both high-volume and low-run projects.

No MOQ for Custom Push Pull Cable Orders

WellPCB accepts all orders with no minimum quantity. We support custom push pull cable assembly builds at any scale, helping you test and deploy without volume restrictions.

Types of Control Cable Assemblies

WellPCB manufactures several types of control cable assemblies, each optimized for a specific application, motion requirement and environmental condition.

Push Pull Cable Assembly

Remote Control Cable Assembly

Electrical Control Cable Assembly

Mechanical Linkage Cable Assembly

Cables Used In Control Cable Assemblies

In addition to traditional mechanical control cables, WellPCB manufactures assemblies using several specialized cable types to meet unique signal, environmental and safety requirements across industrial and defense applications.

RF Cable Assemblies

RF cables support high-frequency communication and sensor control within complex control systems.

These assemblies use precision connectors and low-loss fluoropolymer dielectrics to maintain transmission quality and reliable performance in aerospace and defense applications.

Coaxial Cable Assemblies

Coaxial cables are used in control cable assemblies requiring stable impedance and minimal signal loss.

They feature a concentric conductor and dielectric structure with braided copper shielding to maintain signal integrity in automation and test systems operating up to several hundred megahertz.

Low Smoke Zero Halogen (LSZH) Cables

LSZH cables are designed for confined or public environments such as tunnels, vehicles and buildings where safety and fire performance are critical.

Their halogen-free insulation limits toxic emissions and smoke density while maintaining flexibility and mechanical durability.

Fiber Optic Control Cables

Fiber optic control cables provide EMI-immune signal control for robotics, smart city infrastructure and automated process equipment.

Using glass or polymer optical fibers, these cables transmit control data over long distances without interference or voltage drop.

Where are Control Cables Used?

Control cable assemblies play a huge role in systems that require reliable motion, signal or force transfer under load. Their use spans across industries that demand accuracy, durability and environmental resistance.

Industrial Automation

Control cable assemblies connect actuators, sensors, and controllers.

They support machine movement, real-time feedback loops and emergency shutoff systems where precise motion and signal integrity are non-negotiable.

Transportation and Aerospace

Push pull control cables and mechanical control assemblies are used in automotive, rail and aerospace systems for throttle, clutch, brake and rudder control.

Built to withstand vibration, thermal cycling and mechanical stress, these cables use reinforced conduit and corrosion-resistant end fittings to meet mission-critical demands.

Renewable Energy & Power

In wind turbines and solar farms, control cable assemblies manage actuator positioning, louver controls and monitoring system interfaces.

These cables are designed with UV-resistant jackets, shielded signal paths and weather-sealed accessory components for long-term field reliability.

Medical Equipment

From robotic surgery arms to adjustable hospital beds, custom control cables provide smooth, safe movement where accuracy and hygiene are key.

Low-friction liners, sealed end fittings and soft routing profiles help these assemblies fit compact spaces without sacrificing performance or safety.

Control Cables’ Technical Specification

| Parameter | Specification Range | Why It Matters |

|---|---|---|

| Conductor Material | Stainless steel, carbon steel, tinned copper | Determines strength and corrosion resistance |

| Wire Gauge | 10 AWG to 28 AWG | Matches load and signal requirements |

| Insulation Material | PVC, TPE, rubber, PTFE | Defines temperature range (-40 °C to 105 °C) and flexibility |

| Voltage Rating | Up to 600 V | Prevents breakdown under industrial loads |

| Operating Temperature | -40 °C to +105 °C | Supports harsh environment operation |

| Tensile Strength | > 1,000 N (typical push pull) | Ensures mechanical reliability |

| Mating Cycles | 500 + cycles | Indicates durability of fittings and connections |

| Certifications | UL, CSA, IPC/WHMA-A-620 Class 3, MIL-DTL | Guarantees industry compliance and safety |

How to Order Your Control Cable Assembly

Submit Your Design

Send us your design details (Drawing or Detailed Specifications).

Get a Fast Quote

Once your design and specs are received, a fast quote will be sent to you within 24 hours.

Confirm Order & Make Payment

When the quotation is approved, please send the PO or order confirmation, we will proceed with the production after receiving your payment.

Arrange Production & Inspection

Before production, our technical team will review all details of the drawing/specs again. If everything is OK, the order will start. We'll keep you updated throughout the manufacturing process. After the production is completed, the products will be 100% inspected.

Packaging & Delivery

When completed, your order will be carefully packed and shipped to you, with shipping documents and tracking information provided.

WellPCB is trusted by millions of

businesses and innovators.

Why Choose WellPCB as Your Wire Harness Manufacturer?

WellPCB stands out among USA wire harness manufacturers by delivering superior quality, advanced solutions, and unmatched reliability. With years of experience serving global markets, WellPCB has earned a reputation as one of the top wire harness manufacturers in the USA.

WellPCB specializes in custom wire harnesses for complex electronic and industrial applications. You can order these assemblies with $100 off using our special offer—delivering high-quality, tailor-made harnesses at competitive rates for your most demanding projects.

Hommer Zhao

Founder and Chief Editor – Hommer Zhao

Welcome! I’m Hommer Zhao, the founder and Chief Editor of WellPCB. With years of experience in the PCB industry, I’m committed to making sure our content is both accurate and helpful. We’re proud to serve a growing community of over 4,000 customers worldwide, and our goal is to provide you with the best resources and support. Your satisfaction is our top priority, and we’re here to help you every step of the way!

Jesse Holland

Technical Manager – Jesse Holland

Hi, I’m Jesse Holland, an Engineer and Technical Manager at WellPCB. With years of experience in PCB design and engineering, I’m here to ensure that every project we work on meets the highest technical standards. I lead our team, focusing on precision and innovation, collaborating closely with clients to provide tailored solutions and expert guidance. Whether you’re facing a complex design challenge or need advice on technical aspects, I’m here to ensure your project is a success from start to finish.

Nathan Jensen

Purchasing Manager – Nathan Jensen

Hi, I’m Nathan Jenson, the Purchasing Manager at WellPCB. I’m responsible for sourcing the best materials and components to ensure our products meet the highest quality standards. With my extensive experience in procurement, I work closely with suppliers to secure reliable and cost-effective solutions while maintaining strong relationships to support our operations. I aim to ensure every project runs smoothly by providing the resources needed to deliver on time and to your satisfaction.

Emma

Sales Manager – Emma

Hey, I am Emma, sales manager at WellPCB. I studied electronic science and technology at university and have served customers for PCB and PCB Assembly service for several years.

I enjoy communicating with customers and our technicians to solve problems, and customers always say, "It's great to have you onboard".

It is my pleasure and honour to be helpful. Contact me now, and you'll know.

Bella and Cassiel

Sales Representatives – Bella and Cassiel

We’re Bella and Cassiel, your dedicated sales representatives at WellPCB. With our extensive knowledge of the PCB industry, we’re here to provide exceptional service and support. We take the time to understand your unique needs and are always ready to offer tailored solutions and advice. Whether you need product recommendations, assistance with your orders, or simply have a question, we’re here to ensure your experience is smooth and seamless at every step.

Mandy and Wendy

Sales Representatives – Mandy and Wendy

We’re Mandy and Wendy, your friendly sales representatives at WellPCB. Passionate about helping our customers, we bring a wealth of experience in the PCB industry to provide you with the best solutions and service. We take pride in building strong relationships with our clients, understanding their specific needs, and offering personalised support to ensure their satisfaction. Whether you’re looking for advice, product information, or assistance with any part of your order, we’re here to make your experience as smooth and efficient as possible.

Our Team

Our skilled engineers and technicians bring expertise and precision to every PCB assembly project. Committed to quality, efficiency, and innovation, our team ensures every order meets the highest UL, IPC, ROHS & REACH standards, delivering reliable solutions tailored to your needs.

- Founder and Chief Editor – Hommer Zhao

- Technical Manager – Jesse Holland

- Purchasing Manager – Nathan Jensen

- Sales Manager – Emma

- Sales Representatives – Bella and Cassiel

- Sales Representatives – Mandy and Wendy

Waterproof Wire Harness Case Studies

PCB Assembly

The picture shows an HDMI-to-DVI cable with USB power. It can be used to connect HDMI-enabled devices (such as laptops and TV boxes) to DVI-equipped monitors and other home appliances.

Advantages:

- •Strong Compatibility: Allows connection between devices with different interface standards, expanding their use cases.

- •Stable Transmission: Provides stable video signal transmission, minimizing interference and loss during signal transmission.

- •Convenient Power Supply: No need to find a separate power source, making it more convenient to use.

PCB Assembly

The picture shows an HDMI-to-DVI cable with USB power. It can be used to connect HDMI-enabled devices (such as laptops and TV boxes) to DVI-equipped monitors and other home appliances.

Advantages:

- •Strong Compatibility: Allows connection between devices with different interface standards, expanding their use cases.

- •Stable Transmission: Provides stable video signal transmission, minimizing interference and loss during signal transmission.

- •Convenient Power Supply: No need to find a separate power source, making it more convenient to use.

PCB Assembly

The picture shows an HDMI-to-DVI cable with USB power. It can be used to connect HDMI-enabled devices (such as laptops and TV boxes) to DVI-equipped monitors and other home appliances.

Advantages:

- •Strong Compatibility: Allows connection between devices with different interface standards, expanding their use cases.

- •Stable Transmission: Provides stable video signal transmission, minimizing interference and loss during signal transmission.

- •Convenient Power Supply: No need to find a separate power source, making it more convenient to use.

Control Cable Assembly Client Feedback

As an R&D manager, I have had an outstanding experience working with WELL-PCB. For many years, our company has entrusted them with the production, assembly, and programming of the boards developed in our R&D unit, and they have consistently exceeded our expectations.

Hamid Reza Moshayedi

R&D Manager

Their work is very impressively perfect. Today, when they check our company PCB board after assemble. They found a fake short point which many engineers has never found in the past years. But that is just designed so. The PCB board quality is excellent. Their service is also excellent.

MikeZ

My friend introduced WellPCB to me, the first try, a little look forward to. I ordered a 47*72 10ps PCB, and I can’t wait to receive my PCB. So I used expedited service and received my PCB in three days. I tested and soldered the PCB, Quality is really good, silkscreen, plating also great.

Warren Cliton

Control Cable Assembly FAQs

Why are control cable assemblies important?

A control cable assembly links a user’s physical input, like moving a lever or turning a knob, to a machine’s mechanical or electrical actuation system. Whether you’re controlling a throttle, brake or remote valve, these assemblies provide precise control over force or signal transmission. Without properly engineered control cables, alignment issues, friction loss or stretch could lead to equipment failure, delayed response, or operator fatigue.

Can you manufacture custom push pull cables for specific load or temperature ranges?

Yes, we manufacture custom push pull cable assemblies tailored to your specific application, load rating and environmental conditions. Our assemblies can withstand mechanical loads above 1,000 N and operate reliably from -40 °C to +105 °C. Options include high-strength wire cores, PTFE-lined conduit for low-friction movement and ruggedized casing materials tested for field performance. We customize the full cable structure to meet performance specs without overbuilding.

What quality control and testing methods do you use?

Every control cable assembly is tested for quality and reliability using industry-standard tools and procedures. This includes tensile load testing with digital pull testers, Hi-Pot testing for insulation up to 600 V and Cirris-based continuity testing to identify shorts or open circuits. Each assembly is visually inspected, labeled and tracked by operator and lot for traceability. For cable assemblies with motion requirements, we validate return-to-center performance and casing compression under load.

What certifications and compliance standards does WellPCB follow?

All control cable assemblies are manufactured under ISO 9001 and IATF 16949 quality systems and built to IPC/WHMA-A-620 Class 3 workmanship standards. Our facility and materials comply with UL, RoHS and REACH regulations, and testing follows OSHA and EPA environmental guidelines. These certifications ensure every assembly meets rigorous global standards for reliability, safety and environmental responsibility.

What do your certifications actually mean?

Our certifications guarantee each control cable meets industry-defined standards for materials, workmanship and performance. IPC/WHMA-A-620 Class 3 certification means your assembly is built for high-reliability environments like aerospace, automotive or industrial automation. ISO 9001 and IATF 16949 confirm our manufacturing system meets global quality management standards. UL and RoHS compliance certify that the components, wire styles and production methods meet North American safety and environmental requirements.

Control Cable Assemblies Made to Your Exact Specs

Get $100 Off Your First Order!

Whether you need a prototype or full-scale production, WellPCB is your trusted partner for every control cable assembly project. From ruggedized push-pull cables to complex multi-conductor assemblies, we deliver fast, traceable and fully tested solutions that fit your application perfectly.