Contents

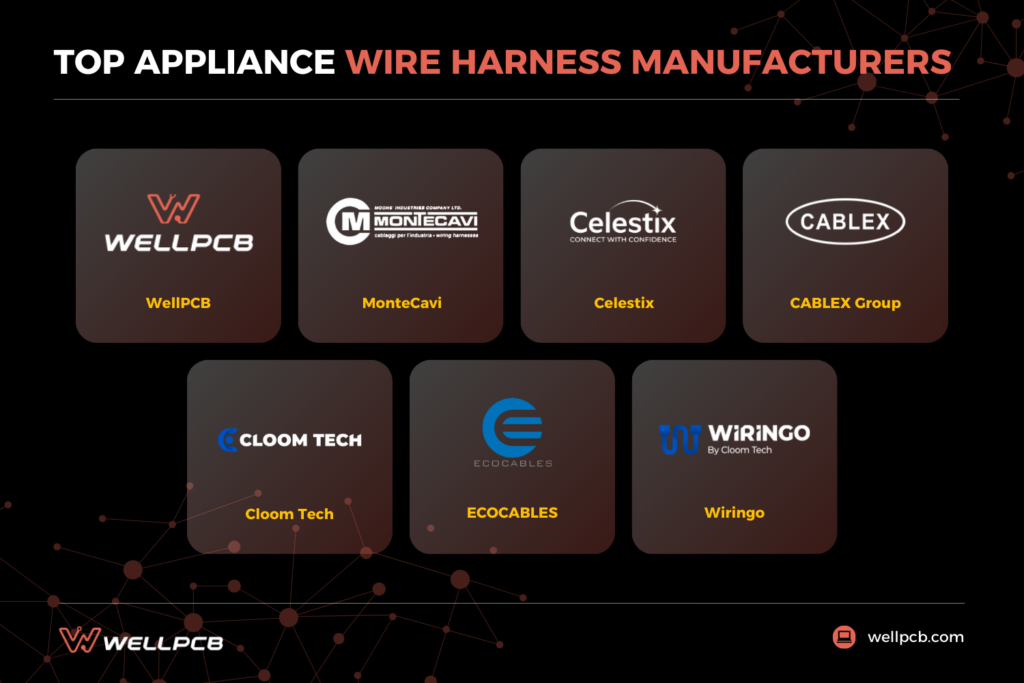

1. WellPCB

WellPCB stands out with its powerful vertical integration, combining PCB fabrication, cable production, and final harness assembly under one roof. This unique model provides appliance OEMs with unmatched control over quality, cost, and supply chain stability. The company operates under a formal quality management system, including ISO 9001 and WHMA (Wire Harness Manufacturer’s Association) practices, which ensures that each wire harness is built with consistent crimping, routing, insulation handling and inspection controls.

WellPCB builds wiring harness and cable assemblies that align with appliance safety and UL expectations, confirming insulation ratings, temperature tolerance and conductor sizing for real operating conditions in home appliance platforms. Material control is handled through approved sourcing of terminals, connectors and cable components, reducing variation across production runs.

From pilot builds to full-scale harness manufacturing, WellPCB supports flexible volumes without compromising quality. Clear documentation, revision control and change management help appliance OEMs transition designs smoothly while maintaining reliable performance.

| Pros | Cons |

|---|---|

| ✅ True Vertical Integration: One partner for PCB, cable, and harness assembly, reducing supply chain complexity and cost. | ❌ Limited off-the-shelf wire harness inventory, which may not suit urgent replacement needs. |

| ✅ Offers cost-effective manufacturing services for both low-volume and high-mix builds. | |

| ✅ Holistic DFM Support: Engineering feedback that considers the entire system, from PCB layout to harness routing, for optimal performance and manufacturability. |

2. MonteCavi

Montecavi Group is a European cable and wire harness manufacturer with a strong focus on wiring harnesses for household and professional appliance systems. The company brings decades of experience in cable harness manufacturing, supporting appliance wire harnesses that must withstand thermal stress, vibration and continuous operation in demanding environments.

Its production model emphasizes structured wiring layouts, controlled assembly sequences and repeatable workmanship, which supports stable output across long-running appliance programs.

Montecavi demonstrates compliance with appliance safety expectations through testing aligned with European and international electrical requirements. The company maintains close control over wiring materials, terminals and connectors, which helps limit variation across batches for high-volume customers.

With manufacturing operations scaled for serial production, Montecavi supports appliance manufacturers that require consistent builds, documented changes and reliable wiring solutions across evolving product lines.

| Pros | Cons |

|---|---|

| ✅ Emphasis on structured assembly workflows that support consistent wiring layouts across repeat production cycles. | ❌ European-centered operations may present cost or logistics challenges for customers sourcing primarily outside the region. |

| ✅ Proven capability to support appliance manufacturers managing multi-year product platforms. | |

| ✅ Strong European manufacturing footprint that appeals to appliance OEMs seeking regional production. |

3. Celestix

Celestix Industries has dedicated high-quality offerings for home appliance wiring harness systems. The company positions itself around practical wiring solutions designed for durability, repeatability and volume consistency, which are essential in the appliance industry where long production runs are common.

Celestix aligns its wire harness manufacturing with international appliance safety and electrical requirements, helping confirm that wiring and terminals meet the expected temperature and load conditions. Material selection and component sourcing are carefully managed to support consistent builds across appliance programs.

With production structured for high-volume output, Celestix supports appliance OEMs that require dependable wiring harnesses for household products, documented processes and steady manufacturing services as designs evolve.

| Pros | Cons |

|---|---|

| ✅ Production model suited to medium- and high-volume appliance programs. | ❌ Less emphasis on low-volume prototyping compared to engineering-heavy suppliers. |

| ✅ Emphasis on practical, application-driven wiring layouts for household use. | |

| ✅ Supports stable, repeatable harness manufacturing for long product lifecycles. |

4. CABLEX Group

Cablex Group is a globally established wire harness manufacturer, coordinating complex wiring cable and connector integration while maintaining consistency across international manufacturing sites.

The company emphasizes compliance with appliance safety and electrical expectations through standardized processes, controlled material selection and documented assembly methods. Its scale allows appliance OEMs to move from early production to high-volume output quickly without disrupting harness design or quality levels.

Strong documentation practices and change management help support model updates and regional variations, making them a good choice for global appliance programs requiring reliable wiring solutions across markets.

| Pros | Cons |

|---|---|

| ✅ Global manufacturing footprint suited to multinational appliance OEMs. | ❌ May be less cost-competitive for simple or short-run appliance harness builds. |

| ✅ Long track record working with large appliance brands. | |

| ✅ Strong experience coordinating cross-border logistics. |

5. Cloom Tech

Cloom Tech is an OEM-focused appliance wire harness assemblies manufacturer, with a clear emphasis on build-to-print execution and engineering collaboration. The company supports appliance wiring programs that require precise routing, controlled termination, and consistent workmanship across repeated production runs.

Cloom Tech places strong emphasis on documentation accuracy and revision discipline, helping appliance OEMs manage design updates without introducing build risk. Material selection, terminal processing and connector integration are handled with attention to repeatability, supporting stable output across evolving appliance models.

The company’s structure favors manufacturers that need predictable execution and clear communication throughout the wire harness manufacturing process.

| Pros | Cons |

|---|---|

| ✅ Strong OEM alignment with clear build-to-print and revision-control workflows. | ❌ Not ideal for buyers seeking catalog-style or off-the-shelf wiring solutions. |

| ✅ Responsive engineering support during design clarification and change cycles. | |

| ✅ Flexible enough to support both appliance and adjacent industrial applications. |

6. ECOCABLES

ECOCABLES positions itself as a specialized manufacturer focused on home appliance wiring harness solutions. The company emphasizes functional layouts and practical harness construction, supporting appliance systems where space constraints, heat exposure and continuous operation are key considerations.

This manufacturer highlights controlled assembly practices and component selection to support repeatable builds, particularly for appliance wiring that integrates into compact enclosures and control interfaces. Their approach favors straightforward execution and predictable output rather than highly customized engineering programs.

Documentation and process consistency support ongoing production while helping customers manage incremental updates to appliance models.

| Pros | Cons |

|---|---|

| ✅ Straightforward manufacturing model suited to standardized appliance designs. | ❌ Limited emphasis on advanced customization or complex harness architectures. |

| ✅ Focus on practical wiring layouts for compact household equipment. | |

| ✅ Accessible supplier option for appliance programs with stable specifications. |

7. Wiringo

Wiringo operates as a custom appliance wire harness manufacturer, offering wiring designs based on customer drawings rather than fixed, catalog-based products. Their approach aligns well with appliance projects that evolve through multiple design iterations before reaching stable production.

The company highlights flexibility in materials, wiring configurations and harness construction, providing to OEMs rather than individuals or small shops. They favor small-to-midsize production volumes and diversified product lines rather than mass-standardized appliance platforms.

This makes Wiringo a practical option for OEMs seeking tailored wiring solutions with responsive communication and manageable change cycles.

| Pros | Cons |

|---|---|

| ✅ Strong focus on custom wire harness solutions and non-standard configurations. | ❌ No design services offered, although they do DFM checks. |

| ✅ Excellent supplier partnerships for quick, affordable sourcing. | |

| ✅ Responsive communication during specification and revision stages. |

What to Look for in Appliance Wire Harness Manufacturers

Proven Quality Systems

Electrical wire harnesses must perform consistently over long service lives. Choose manufacturers with established quality systems that control crimping, routing, insulation handling and final inspection to reduce field failures and warranty risk.

Compliance With Appliance Safety Standards

Manufacturers should build harnesses that align with appliance safety and electrical standards, such as UL requirements. This helps confirm insulation ratings, temperature tolerance and conductor sizing match real-world operating conditions.

Material and Component Control

Reliable suppliers manage approved sources for wire terminals, connectors and sleeving. Consistent material control supports repeatable builds and reduces variation across production runs, especially for high-volume appliances.

Manufacturing Scale and Flexibility

Appliance programs often move from pilot builds to large production volumes. A capable manufacturer should support prototypes, pre-production and full-scale output without changing processes or quality levels.

Documentation and Change Management

Clear drawings, revision control and documented process changes matter when appliance models evolve. Strong documentation helps prevent build errors and supports smooth transitions during updates or supplier changes.

Back to Top: Top Appliance Wire Harness Manufacturers