1. WellPCB

WellPCB tops most robotics cable assembly manufacturers because they’re a one-stop shop delivering complete robotic cable assemblies, wire harnesses and PCB integration for automation and robotics applications.

With two PCB factories and two dedicated cable assembly facilities (in Shenzhen and Shijiazhuang), the company combines PCB manufacturing, component sourcing and custom cable production under one supply chain. This unified workflow minimizes handoffs, reduces the risk of cable failures and shortens the turnaround time for robotic systems.

Each of their robotic cable assemblies and all parts (cables, connectors, etc.) is built to IPC/WHMA-A-620 Class 3 and ISO 9001 standards, ensuring repeatable quality for robotic applications, medical equipment, aerospace wire harness systems, and industrial automation.

WellPCB’s advanced production line supports robot cables up to 600 V and 105 °C with precision conductor crimping, automated continuity testing, high-flex strain relief and EMI shield optimization for signal integrity. The company also performs Hi-Pot, pull and thermal cycling tests to confirm durability in harsh environments and continuous motion systems.

| Pros | Cons |

|---|---|

| ✅ Supports custom robotic cable and interconnect products for robotic arms, dress packs and energy chains, minimizing downtime in industrial automation systems. | ❌ Tailored cable solutions dominate production, limited off-the-shelf inventory for immediate shipment. |

| ✅ Integrates component sourcing through authorized distributors (Arrow, Avnet, Mouser, Digi-Key, Element14) to guarantee authentic connector and cable materials. | |

| ✅ Performs in-house high-flex life cycle validation exceeding 10 million repeated bending cycles under simulated robot arm motion. |

2. Igus, Inc

Igus, Inc. is a global leader in robotics cable assemblies and motion control components. They’re particularly known for their Chainflex® series of robotic cable systems, which are flexible cables engineered for continuous motion in automation and robotics, maintaining stable electrical performance even under high torsion stress and repeated bending.

Igus designs each robotic cable assembly to meet the mechanical demands of robotic arms and robotic control systems operating in harsh environments. They stock a wide range of cable types so they’re always ready to build something to spec.

The company’s robot cables are tested in its 3,800 m² lab, where over two billion cycles of movement validate durability and signal integrity. Chainflex cables use TPE and PUR outer jackets with EMI shield layers and fine-strand copper conductors to support high-speed data transmission, servo drives and Ethernet connectivity in robotic applications. These designs integrate seamlessly with energy chains, reducing wear in industrial automation and material handling systems.

| Pros | Cons |

|---|---|

| ✅ Offers 1,350+ specialized cables rated for high torsion and continuous motion within robotic energy supply systems. | ❌ Pricing is higher than average due to extensive laboratory verification and global logistics support. |

| ✅ Pre-certified connector and cable assemblies for Ethernet, RF and power and data lines ensure plug-and-play integration. |

3. Victor Wire & Cable

Victor Wire & Cable (VWC) has over 50 years of experience in custom cable and robotics cable manufacturing, specializing in high-flex designs for automation and motion-intensive systems. Their robotics cables combine specialized conductors and rugged jacketing to endure continuous bending and harsh operating conditions.

VWC offers custom industrial cables tailored to specific robotic applications, enabling integration of power, feedback and control circuits into compact robotic cable assemblies for industrial automation.

Victor’s robotics cable products use fine-stranded copper conductors with polymeric insulation (such as PUR or TPE) and abrasion-resistant outer jackets to resist mechanical stress. Their design focus is on long working life under dynamic flex, with ratings that emphasize durability in repeated bending environments.

They work with UL and MIL-SPEC certifications to support use in robotic systems, material handling and machine tools.

| Pros | Cons |

|---|---|

| ✅ Able to co-design integrated signal and power cores within a single cable to reduce bulk and improve signal integrity. | ❌ Their specialization in custom robotics cables means standard off-the-shelf parts may have longer lead times. |

| ✅ Proven in applications where long flex life is essential, thanks to proprietary conductor geometries. | |

| ✅ Offers flexibility in customizing conductor gauge, insulation material and jacket compound to match the mechanical strain profile of each robot axis. |

4. ICS Manufacturing

ICS Manufacturing (Integrated Cable Systems), based in Colorado, is ISO 9001:2015 and AS9100D certified, a dual certification not often seen among robotics cable assembly manufacturers.

They specialize in custom cable assemblies and electro-mechanical assembly services that integrate wire harness subassemblies, overmolding and full system integration for robotic systems.

What sets ICS apart is their strategic positioning within the Trexon family, which grants them access to an extended supplier network and advanced manufacturing technologies that reduce component cost and shorten lead times for complex assemblies.

ICS applies rigorous mechanical and electrical testing on its robotic cable lines, including flex fatigue, insulation-resistance and environmental stress screening, assuring stable electrical performance under continuous motion and temperature cycles in harsh environments.

Their assemblies often combine signal, power and data transmission cores within compact overmolded housings, ideal for robotic applications requiring a small footprint.

| Pros | Cons |

|---|---|

| ✅ Direct access to Trexon’s shared engineering database improves design repeatability and standardization across automation and robotics projects. | ❌ Engineered-to-order production model means they don’t really do standard stock assemblies. |

| ✅ Uses class-100,000 clean assembly areas to prevent contamination of fine-pitch connector systems and ensure stable impedance. | |

| ✅ Certified to AS9100D and offering batch traceability, ICS suits applications in aerospace and defense as well as industrial robotics. |

5. Junkosha Inc.

Junkosha Inc. is a Japanese specialist in flat and high-flex cables and robotic cable solutions, well known for integrating power, signal and even hydraulic and pneumatic lines into unified cable designs. Their EHF-01 series uses fluoropolymer jackets for superior chemical resistance and multi-movement durability.

Junkosha tailors conductor types (A, C, D, ME1/ME2/ME7) and insulation materials (ETFE, EPTFE) to meet specific flex-life, electrical and packaging requirements.

These cable assemblies are built for robotic applications, especially in semiconductor, precision robotic systems and machine-tool environments. They deliver resistance to oil, chemicals and outgassing, making them suitable even in cleanrooms.

Their ability to combine electrical and fluid control lines is a feature that nudges them ahead of other mainstream robotics cable assembly manufacturers.

| Pros | Cons |

|---|---|

| ✅ Offers conductor and insulation variants tailored by flex-life, allowing optimization between cost, cycle life, and electrical performance. | ❌ Because of its specialization and material complexity, pricing is premium compared to generic high-flex cables. |

| ✅ Fluoropolymer or ETFE jackets deliver exceptional chemical resistance, abrasion resistance, and minimal outgassing in vacuum or clean environments. | |

| ✅ Supports flat, round, or curled geometries, enabling space-efficient packaging in tight robotics systems designs. |

6. Habia Cable

Habia Cable (including its HEW-KABEL lineage) offers dedicated robotics cabling solutions engineered for the severe demands of modern robotic arms, collaborating robots, painting robots and welding robots.

Their specialty is in producing custom cables & harnesses that resist chemical, thermal, mechanical and abrasion stresses under continuous motion and torsion across multiple robot axes.

Habia supports full development from concept to qualification: they maintain in-house prototyping and testing (including pressure tank testing, mechanical resistance validation, and full electrical inspection) ensuring every cable-harness meets specifications before deployment.

Their global manufacturing footprint (Sweden, Germany, China, Poland) enables agility in scaling tailored solutions while retaining rigorous quality.

| Pros | Cons |

|---|---|

| ✅ All-integration R&D and test labs allow early failure analysis, shortening development cycles. | ❌ Highly customized solutions may have a higher per-unit cost compared to standard high-flex robotic cable assemblies. |

| ✅ Broad material expertise (PTFE, fluoropolymers, halogen-free compounds) to tailor jacket options for specific robotic applications. | |

| ✅ Low-volume runs are feasible due to Habia’s multi-site production flexibility across continents. |

7. P&D Cables

P&D Cables specializes in 3-dimensional robotic cables, designed for dynamic robotic arms that move across multiple axes. Their cables are engineered to handle the twisting, flexing and extension associated with automation and robotics while maintaining continuous electrical performance. Each robotic cable integrates fine-strand copper conductors, low-friction separators and cross-linked polymer insulation to prevent torsion fatigue and jacket cracking during repeated bending.

P&D’s 3D robotic line includes power, signal integrity and data transmission circuits within a single compact construction. Shielded versions provide strong EMI protection for robotic control and servo systems.

Their custom jacket materials resist abrasion, weld spatter, oil and chemicals, ensuring durability and flexibility in harsh environments such as welding, painting and assembly lines. These cables are used by major robotics OEMs and industrial automation integrators seeking reliable, motion-rated cable solutions.

| Pros | Cons |

|---|---|

| ✅ In-house design and testing of robotic cable assemblies ensure predictable flex-life and minimized downtime in robotic applications. | ❌ Limited published specifications; custom data sheets typically provided only upon request. |

| ✅ Patented 3-axis cable geometry reduces torque stress on the robot arm during synchronized multi-directional motion. | |

| ✅ Offers hybrid builds combining power and data circuits for simplified robotic systems integration. |

8. Y.C Cable

Y.C Cable is a professional custom cable and robotics cable assembly manufacturer with over 30 years of experience producing precision interconnect solutions for automation and robotics. Their custom robotic cable products combine power, control and data transmission cores within compact, high-flex jacket structures. Each assembly is built in ISO 9001-certified facilities using automated stripping, crimping and soldering systems to maintain consistent electrical performance and signal integrity under continuous motion.

Y.C Cable’s robotic cables employ finely stranded copper conductors, high-flex TPE insulation and braided shield layers to suppress EMI and static buildup during repetitive robotic articulation. TThey also integrate waterproof and overmolded connector and cable systems to support harsh environments, from material handling equipment to medical cable assemblies for surgical robots and diagnostic equipment. As an experienced OEM wire harness manufacturer, their design engineering team provides tailored solutions for OEMs that need lightweight routing through energy chains, dress packs and compact robotic enclosures.

| Pros | Cons |

|---|---|

| ✅ Advanced overmolding and waterproofing options extend durability in oil, coolant, and chemical-exposed environments. | ❌ Highly customized specialized cables may require longer verification cycles before mass production. |

| ✅ Proven ability to co-design robotic cable assemblies optimized for high-speed data and servo signal transmission. | |

| ✅ Strong production scalability for both prototype and mass-volume robotic systems, backed by automated inspection and pull-testing. |

9. SAB Bröckskes

SAB Bröckskes is one of Europe’s most established robotic cable manufacturers, known for its SAB Cleanroom, SAB Servo and SAB Flexible series designed for industrial automation and robotic applications. Their robot cables are tested to withstand over 10 million flex cycles and ±360° torsion movement, maintaining stable electrical performance during high-speed, multi-axis operation.

Each cable incorporates ultra-fine stranded conductors, halogen-free TPE or PUR jackets and multi-layer EMI shield systems to suppress noise in servo, feedback and control systems. SAB’s robot cables are approved to VDE and UL standards and used in automation and robotics, machine tools and material handling systems exposed to oil, chemicals, and harsh environments.

SAB also provides hybrid connector and cable configurations supporting power and data transmission through single flexible assemblies, reducing installation time and failure points.

| Pros | Cons |

|---|---|

| ✅ Extensive robot cables portfolio rated for dynamic flexing, torsion, and chemical exposure under continuous robotic operation. | ❌ Customized tailored solutions with non-standard jackets or conductor materials can extend both cost and lead times. |

| ✅ Hybrid cable assemblies integrate power and data circuits for compact routing and minimal cable wear. | |

| ✅ Global production and distribution capability with strong OEM support for robotics industry customers. |

10. JEM Electronics

JEM Electronics is a US-based manufacturer of robotics cable assemblies and wire harness systems for robotic systems. With ISO 9001 and IPC/WHMA-A-620 certifications, JEM provides custom robotic cable and connector configurations built to withstand continuous motion and vibration common to robot arms and mobile robotics.

The company specializes in precision overmolded interconnect products, high-strand copper conductors and EMI shield assemblies optimized for signal integrity and data transmission in harsh environments. JEM’s robotic lines include hybrid power and data cables, RF and feedback loops and control cable assembly systems for quick-connect servo applications.

Their in-house testing covers electrical performance, pull strength, flex endurance and environmental validation, which are essential for mission-critical robotic applications requiring predictable performance.

| Pros | Cons |

|---|---|

| ✅ Custom-engineered robotic cable assemblies with precise strain-relief geometry to minimize field failures. | ❌ Longer prototype turnaround times for highly customized specialized cables with unique connector molds. |

| ✅ Offers full system documentation, from material traceability to test reports, aiding compliance for aerospace and defense contracts. | |

| ✅ Strong domestic engineering support for OEMs developing next-generation automation and robotics equipment. |

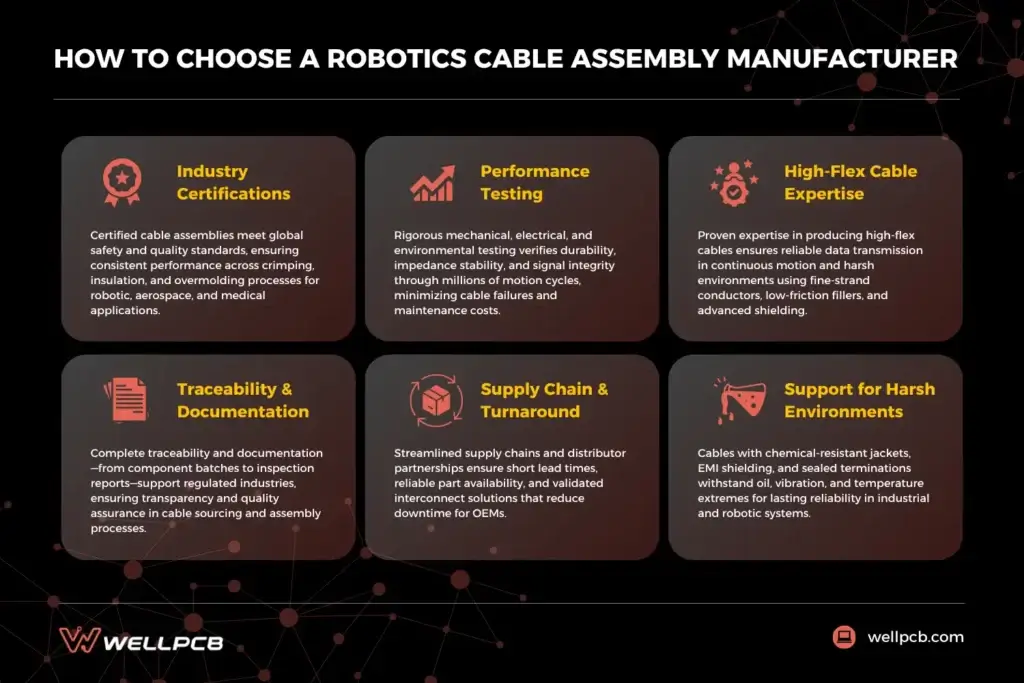

What to Look for in Robotics Cable Assembly Manufacturers

Industry Certifications

Industry standards and certifications confirm that a manufacturer’s cable assemblies meet global quality and safety requirements. These standards govern every stage of assembly, from conductor crimping to insulation and overmolding, ensuring repeatable quality across robotic systems used in industrial automation, aerospace and medical wire harness applications.

Performance Testing

Reliable robotic cable assemblies undergo mechanical, electrical and environmental testing. Methods include Hi-Pot, continuity, torsion and abrasion resistance validation under repeated bending. Such testing confirms electrical performance, stable impedance and signal integrity across millions of motion cycles, reducing field cable failures and maintenance costs.

High-Flex Cable Expertise

Manufacturers must demonstrate proven capability in producing high-flex and highly flexible cables designed for continuous motion and harsh environments. Key features include fine-strand conductors, low-friction fillers and precision shield systems that maintain data transmission quality in robotic control and servo applications.

Traceability & Documentation

End-to-end traceability (from component batch numbers to inspection reports) allows verification of every connector and cable used. Full documentation supports regulated sectors such as aerospace and defense, where transparency in material sourcing and assembly control is essential for quality assurance.

Supply Chain & Turnaround

An optimized supply chain ensures shorter lead times, consistent part availability and dependable technical support. Manufacturers who partner with trusted distributors (such as Helukabel, igus, or TE Connectivity) provide validated interconnect solutions, ensuring reliable cable performance while helping OEMs reduce downtime.

Support for Harsh Environments

In robotic applications, cables must tolerate extreme conditions including oil, weld spatter, vibration and temperature fluctuations. Look for tailored solutions with chemical-resistant jackets, EMI shielding and moisture-sealed terminations. These design elements enable long-term reliability in demanding environments such as machine tools, material handling and automation and robotics systems.

Back to Top: Robotics Cable Assembly Manufacturers | Robot Cable Solutions