Contents

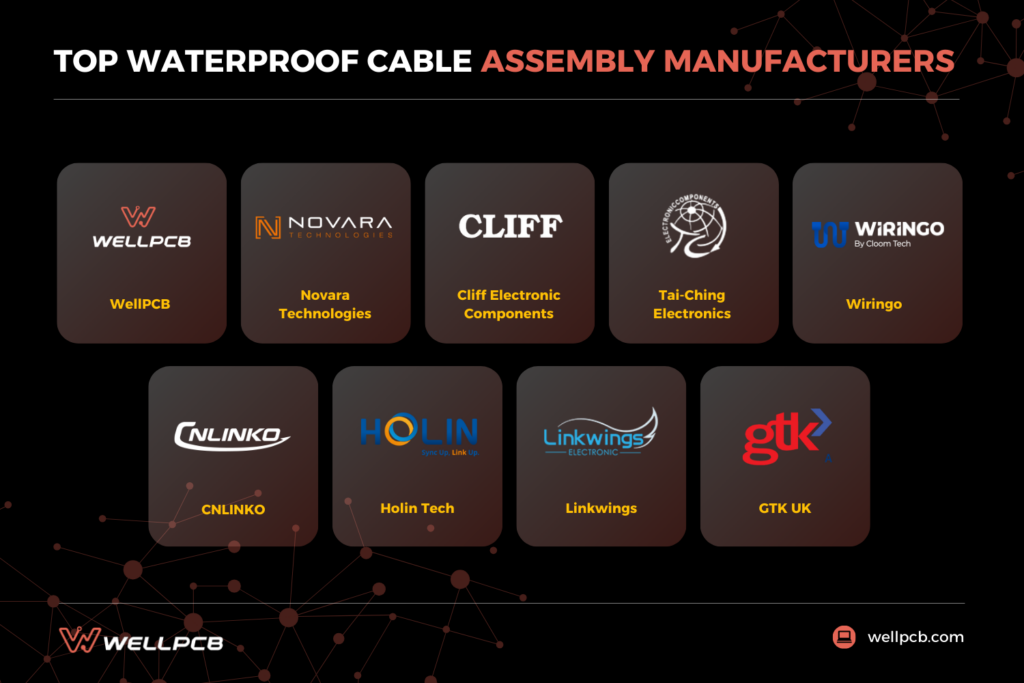

1. WellPCB

WellPCB delivers proven waterproof reliability, not just datasheet promises. Their strength lies in a holistic manufacturing approach that treats the entire assembly—from the connector interface to the overmold geometry—as a single, integrated sealing system.

What differentiates WellPCB is its attention to the manufacturing process behind waterproof assembly. Connector interfaces, O-ring compression, gasket placement and overmold geometry are treated as part of a single interconnect system. This approach supports reliable electrical connections in automotive, automation, medical devices and industrial and outdoor use cases where corrosion, saltwater and abrasion are real risks.

WellPCB’s design and manufacturing workflow also supports prototype builds through scaled production without altering sealing methods or materials.

| Pros | Cons |

|---|---|

| ✅ Connector Agnostic Expertise: Deep experience integrating a wide range of sealed connectors (M-series, RJ45, USB, Coax) into reliable, IP-rated assemblies. | ❌ Highly customized waterproof solutions may require longer upfront engineering alignment. |

| ✅ Strong partnerships with global suppliers like Molex, TE Connectivity and more for reliable sourcing. | |

| ✅ Complex Hybrid Assemblies: Proven capability in designing waterproof solutions that reliably integrate both high-frequency RF and high-power signals in a single assembly. |

2. Novara Technologies

Novara Technologies places an emphasis on sealed interconnect solutions for harsh environment applications. Its waterproof cable assemblies are designed around long-term exposure scenarios, including immersion, vibration and temperature cycling, where ingress protection depends on system-level sealing rather than individual components.

The company’s experience spans overmolded transitions, waterproof cable connector interfaces and integrated strain relief that help reduce failure points in the field. Novara’s approach reflects careful alignment with IP-rated expectations, including IP67 and IP68 waterproof requirements, supported by controlled sealing methods and material selection aimed at resisting corrosion and water ingress.

Their cable assemblies are commonly used in automotive, industrial and outdoor equipment and automation systems where reliable electrical connections must withstand repeated environmental stress. Novara also supports prototype and low-to-mid volume builds without compromising waterproof integrity as designs mature.

| Pros | Cons |

|---|---|

| ✅ Strong specialization in waterproof assembly designs for ruggedized environments. | ❌ Narrower focus may limit suitability for very high-volume commodity programs. |

| ✅ Suitable for applications requiring non-standard sealing geometries. | |

| ✅ Supports IP‑rated assemblies, including immersion‑tested designs. |

3. Cliff Electronic Components

CLIFF Electronics brings long-standing connector engineering expertise into the waterproof cable assembly manufacturers space, particularly where sealed interconnect performance is needed.

The company’s waterproof cable assemblies focus heavily on connector integrity, sealing interfaces and mechanical retention, which are often the primary failure points in wet or outdoor installations.

CLIFF’s waterproof assemblies emphasize robust connector housings, controlled sealing surfaces and consistent termination quality. Rather than treating waterproofing as an add-on, the company integrates ingress protection into the connector and cable interface itself, supporting stable performance in outdoor applications, industrial and outdoor systems and demanding environments where water ingress and corrosion are ongoing risks.

| Pros | Cons |

|---|---|

| ✅ Proven IP68-rated connector and cable interface designs that prioritize protection. | ❌ Less emphasis on large integrated harness or cable bundle assemblies. |

| ✅ Strong focus on mechanical durability suited to demanding applications. | |

| ✅ Proven use in industrial and outdoor environments with persistent moisture exposure. |

4. Tai-Ching Electronics

TC (Tai-Ching) Cable Assembly focuses on waterproof cable assemblies designed for combined power and signal transmission in wet and demanding environments. They focus on sealed connector interfaces and controlled termination methods that help cable assemblies withstand immersion and long-term exposure without compromising electrical stability.

The company builds waterproof cable assemblies using integrated waterproof connector systems designed to meet IP65 to IP68 requirements.. This system-level approach supports reliable electrical connections in industrial and outdoor applications where corrosion and water ingress are persistent risks.

TC Cable Assembly also supports custom waterproof cable configurations for projects that require defined IP performance rather than generic waterproof claims.

| Pros | Cons |

|---|---|

| ✅ Suitable for compact designs where space limits traditional harness layouts. | ❌ Product range is more specialized around connector-driven designs than full cable harnesses. |

| ✅ Strong focus on combined power and signal waterproof cable assemblies within a single connector system. | |

| ✅ Demonstrated support for up to IP68 waterproof cable assemblies intended for submersion use cases. |

5. Wiringo

Wiringo extends its custom-focused approach into waterproof cable assemblies, supporting projects where sealing requirements might be highly customized. The company emphasizes custom-built wire harness products, matching connector requirements and more to the customer’s specifications.

Wiringo’s waterproof assemblies incorporate sealed connector interfaces and overmolded transitions intended to reduce water ingress at termination points. Rather than standardizing on a narrow connector set, the company supports multiple connector types and cable constructions, allowing customization to meet defined IP rating targets.

This makes Wiringo a practical option for prototype and low-to-mid volume programs where waterproof performance must be validated before scaling.

| Pros | Cons |

|---|---|

| ✅ Capable of producing IP67-rated waterproof cable assemblies for applications exposed to moisture and temporary immersion. | ❌ No off-the-shelf cable options for purchase, customized only. |

| ✅ Supports a wide range of connector and cable combinations with an ability to match to customer’s specs. | |

| ✅ Well-suited for prototype builds and early-stage waterproof validation. |

6. CNLINKO

CNLINKO is widely recognized for its connector-driven approach to waterproof cable assemblies, with designs built around its own industrial connector systems.

Their waterproof assemblies combine matched cables and connectors to provide stable power and signal transmission, with features such as waterproof and dustproof performance, abrasion resistance and anti-interference. They can be customized in length, interface type and core combinations to suit different applications.

They integrate waterproof connector design with cable termination and overmold control, treating the assembly as a complete interconnect rather than a set of individual parts. These structured designs support consistent performance while maintaining flexibility across cable types and connector configurations.

| Pros | Cons |

|---|---|

| ✅ Strong expertise in circular waterproof connector and cable integration. | ❌ Customers strictly needing highly bespoke geometries beyond CNLINKO’s established connector families may be limited. |

| ✅ Connector designs emphasize mechanical locking and vibration resistance. | |

| ✅ IP68/IPX9K ratings for use in harsh and even underwater environments. |

7. Holin Tech

Holin Tech provides waterproof cable assemblies with a strong emphasis on application-specific customization. They allow customers to define connector housing shape and size, pin materials, locking style, overmold resin and geometry, as well as cable characteristics such as temperature rating and chemical resistance.

Rather than limiting projects to a narrow catalog of standard connector formats, its services include customized enclosures, strain reliefs and overmolded designs that can be adapted to space constraints and mechanical packaging requirements in the end equipment.

The company supports projects that need tailored cable assemblies, including options for different enclosure materials (plastic, metal or low-pressure molded polyamide), sensor or connector molding and box-level assembly with PCBs and electronic components. Its waterproofing solutions rely on low-pressure molding watertight encapsulation and controlled overmold shapes designed to fit the target device, helping protect components from moisture while accommodating installation and routing needs.

This makes Holin Tech’s offering well suited to OEMs developing bespoke equipment that requires custom connector geometry, enclosure integration or specific environmental performance, rather than simply adopting off-the-shelf interconnects.

| Pros | Cons |

|---|---|

| ✅ Supports IP67-rated (and higher) waterproof connectors and cable assemblies. | ❌ Customers wanting only quick, purely catalog/off-the-shelf options might not need Holin’s deeper customization capabilities, which are a major focus of its offering. |

| ✅ Flexible customization of connectors, cables and overmolds supports niche or non-standard equipment designs. | |

| ✅ Well-suited for projects with tight mechanical constraints or unconventional routing requirements. |

8. Linkwings

Linkwings Electronic offers cable assemblies and connector solutions, including products for applications where moisture protection is important in outdoor and industrial environments. Its waterproof‑oriented cable assemblies are typically built around its own connector and interconnect platforms, aiming to maintain stable electrical connections when exposed to water, dust and vibration.

The company emphasizes matching cable terminations to the corresponding connector systems so that sealing functions at the interface are preserved in the finished assembly. This connector‑centric approach aligns with many use cases where overall ingress protection is defined primarily by the connector and enclosure interfaces rather than by complex internal harness routing.

Linkwings Electronic supports IP‑rated solutions intended for use in equipment installed outdoors or in industrial settings, where exposure to moisture is expected during normal operation. Within these constraints, customers typically select from the company’s existing connector families and work with Linkwings to define appropriate cable lengths, conductor counts and terminations to match application requirements.

| Pros | Cons |

|---|---|

| ✅ Strong linkage between connector selection and cable termination. | ❌ Cable assembly designs are generally based on Linkwings’ existing connector platforms rather than fully open, connector‑agnostic architectures. |

| ✅ Clear focus on IP‑rated connector and cable solutions for industrial and equipment applications. |

9. GTK UK

GTK UK supplies cable assembly solutions for industrial and electronic applications, with an emphasis on controlled manufacturing and consistent build quality across production runs. Its waterproof cable assemblies are positioned for use where reliable ingress protection and mechanical stability are important, such as outdoor or equipment‑level environments subject to moisture and vibration.

The company places importance on process control during cable assembly manufacture, aiming to keep terminations, sealing features and strain‑relief arrangements consistent from prototype through volume production. This production discipline is well suited to programs where predictable, repeatable performance matters more than frequent design changes.

| Pros | Cons |

|---|---|

| ✅ Established reputation for precision manufacturing and repeatable build quality in cable assemblies. | ❌ May be less flexible for very fast‑changing prototype programs that prioritize rapid design pivots over production repeatability. |

| ✅ Well suited to regulated or long‑running programs that require consistent environmental performance over time. | |

| ✅ Emphasis on production stability rather than purely one‑off bespoke builds. |

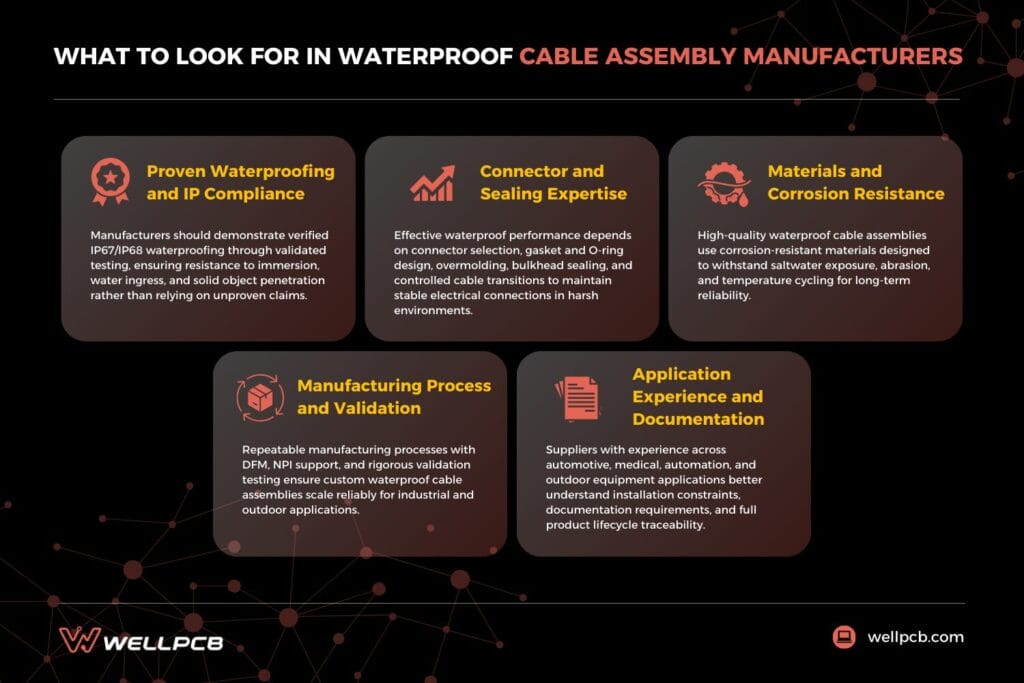

What to Look for in Waterproof Cable Assembly Manufacturers

Choosing the best waterproof cable assembly manufacturers requires more than checking an IP rating on a datasheet. Real-world performance depends on how cables, connectors and sealing systems are designed, manufactured and tested. These five factors help separate reliable suppliers from risky ones.

Look Beyond the IP Rating: Demand Real-World Proof

Manufacturers should demonstrate experience meeting waterproofing standards such as IP67 and IP68, not just claiming them. Look for clear validation against ingress protection requirements, including resistance to immersion, submersion, water ingress and protection against water and solid objects.

Focus on the Interface: Where Waterproofing Succeeds or Fails

Waterproof performance often fails at the connector. Strong suppliers control waterproof connector selection, O-ring and gasket design, overmolded interfaces, bulkhead sealing and cable connector transitions to ensure electrical connections remain stable in demanding environments.

Ensure Long-Term Durability: Scrutinize Material Choices

High-quality waterproof cable assemblies must withstand corrosion, saltwater exposure, abrasion and temperature cycling. Consistent material control across cables, circular connectors, coaxial cable and power cables supports long-term reliability.

Manufacturing Process and Validation

A repeatable manufacturing process, including DFM and NPI support, helps ensure custom waterproof cable assemblies scale without quality loss. Testing should reflect harsh environment and industrial and outdoor use cases.

Application Experience and Documentation

Suppliers serving automotive, medical device, automation, outdoor lighting and outdoor equipment applications tend to understand real installation constraints. Clear documentation and traceability reduce risk across the full product lifecycle.

Back to Top: Top Waterproof Cable Assembly Manufacturers