Contents

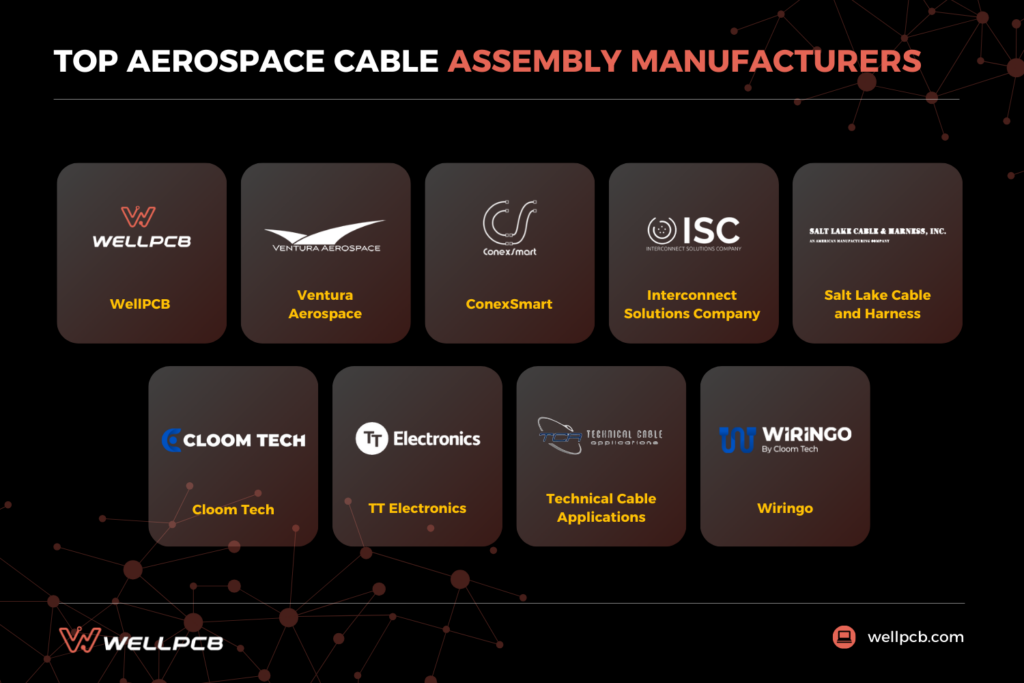

1. WellPCB

WellPCB is a strong fit for aerospace and defense programs that need disciplined, traceable manufacturing without the rigidity of large contract manufacturers. The company supports mission-critical cable assemblies for avionics, flight control and aircraft electronic systems where reliability is mandatory, but program flexibility still matters.

What sets WellPCB apart is their ability to execute build-to-spec aerospace cable assemblies across both low-rate and scaled production while maintaining consistent process control. This makes them a great partner for programs that are moving from early qualification through to sustained production, where volume, timelines and configuration may evolve without warning.

Aerospace cable assemblies are produced under controlled manufacturing processes with full documentation and traceability to support specification compliance across commercial and defense aviation platforms. Rather than optimizing solely for high-volume output, WellPCB balances precision, responsiveness and repeatability, helping aerospace teams maintain momentum while meeting strict program requirements.

| Pros | Cons |

|---|---|

| ✅ Flexible manufacturing model supports prototype through production without requalification. | ❌ Don’t offer design work so customers need to provide their own technical drawings. |

| ✅ Strong documentation and traceability for regulated aerospace programs. | |

| ✅ Well suited for custom, build-to-spec cable assemblies with evolving requirements. |

2. Ventura Aerospace

Ventura Aerospace is best suited for large aerospace programs that prioritize strict specification control and repeatable wire harness execution across multiple aircraft platforms. The company’s strength lies in producing aircraft wire harness assemblies for avionics and flight control systems where configurations are well-defined and change tolerance is low.

Rather than focusing on high-mix or rapidly evolving designs, Ventura emphasizes disciplined assembly techniques and consistency at scale. This makes the company a strong match for established aerospace manufacturers managing complex systems across fleets or long-running aircraft programs where configuration control and uniformity matter more than iteration speed.

Manufacturing is performed within AS9100-certified quality systems that support detailed traceability and configuration management throughout the build process. Ventura’s approach favors stability and predictability, helping aerospace organizations maintain alignment across production runs and aircraft platforms over time.

| Pros | Cons |

|---|---|

| ✅ Deep specialization in aircraft wire harness and harness assembly. | ❌ Less emphasis on high-mix custom cable assemblies outside aerospace. |

| ✅ Strong fit for large, spec-stable aerospace and defense programs. | |

| ✅ Proven experience supporting avionics and flight control systems. |

3. ConexSmart

ConexSmart is an excellent partner for aerospace and defense programs where interconnect performance and electrical precision are the primary design drivers. The company focuses on cable and connector integration for electronic and control systems that demand stable signal transmission, mechanical integrity and tight tolerance execution rather than broad, general-purpose wiring coverage.

Its aerospace cable assemblies are commonly aligned with military, space and high-security platforms where meticulous attention to detail is required at every connection point. ConexSmart’s work emphasizes maintaining signal integrity under demanding operating conditions, making it a strong fit for systems where electrical performance directly affects mission success.

Rather than offering wide-ranging aerospace manufacturing services, ConexSmart concentrates on specialized, precision-driven assemblies. This focused approach benefits programs that require custom interconnect solutions with high electrical accuracy and controlled mechanical performance, particularly in defense-oriented applications.

| Pros | Cons |

|---|---|

| ✅ Strong emphasis on interconnect performance and signal integrity. | ❌ Narrower focus may not suit large aerospace companies who need broad service coverage. |

| ✅ Well-suited for high-precision and security-sensitive aerospace programs. | |

| ✅ Experience supporting military and space-related cable assemblies. |

4. Interconnect Solutions Company

Interconnect Solutions Company is a strong fit for aerospace and defense programs that prioritize process discipline, documentation depth and specification control over speed or iteration.

The company’s manufacturing model emphasizes controlled execution and repeatable quality across complex aerospace cable assemblies. This approach aligns well with programs that demand strict adherence to established requirements, detailed configuration management, and comprehensive documentation throughout the product lifecycle.

Operating within AS9100 and International Traffic in Arms Regulations (ITAR) frameworks, ISC supports aerospace and defense customers that require rigorous process control and audit-ready manufacturing environments. While less flexible for rapid design changes, the company’s structured execution makes it a good match for mature aerospace programs with stable specifications.

| Pros | Cons |

|---|---|

| ✅ Long-standing experience in aerospace and defense manufacturing. | ❌ Less flexible for rapid design iteration cycles. |

| ✅ Strong emphasis on process control and documentation. | |

| ✅ Well aligned with mil-spec and standards-driven programs. |

5. Salt Lake Cable and Harness

Salt Lake Cable and Harness is a good fit for aerospace programs where durability and environmental resilience are the primary requirements. Rather than focusing on highly customized or experimental designs, Salt Lake Cable emphasizes practical manufacturing execution and consistent build quality. This approach benefits aerospace programs that value proven cable constructions capable of withstanding long service life in demanding aircraft environments.

Manufacturing is aligned with AS9100 and International Traffic in Arms Regulations (ITAR) requirements, supporting both commercial and military aviation applications. Salt Lake Cable’s focus on mechanical robustness and repeatable performance makes it a strong option for programs where environmental stress resistance outweighs the need for frequent design changes.

| Pros | Cons |

|---|---|

| ✅ Strong emphasis on durability and performance in harsh aerospace environments. | ❌ Less emphasis on highly customized aerospace cable designs. |

| ✅ Well-suited for power and control cable assemblies in aircraft systems. | |

| ✅ Supports both commercial and military aviation programs. |

6. Cloom Tech

Cloom Tech is best suited for aerospace programs that require custom, design-intensive cable assemblies and close engineering involvement. The company’s strength lies in supporting aircraft wire harness and cable assembly builds where unique requirements, tight mechanical integration, and non-standard configurations are common.

Rather than optimizing for high-volume repetition, Cloom Tech focuses on build-to-spec execution with flexibility built into the process. This makes the company particularly effective for prototype, new product introduction (NPI) and early-stage aerospace programs where designs are still being refined and engineering clarification is frequent.

Cloom Tech supports aerospace and defense applications with disciplined manufacturing aligned to industry expectations, while maintaining a responsive approach to design feedback and change management. This balance of specification adherence and adaptability makes it a strong partner for teams developing custom aerospace electronic systems before transitioning to long-term production.

| Pros | Cons |

|---|---|

| ✅ Strong capability in custom aerospace cable and wire harness assembly. | ❌ Less optimized for very high-volume aerospace production. |

| ✅ Responsive engineering support for design clarification. | |

| ✅ Well-suited for prototype and NPI aerospace programs. |

7. TT Electronics

TT Electronics is best suited for large-scale aerospace and defense programs that require enterprise-level contract manufacturing and long-term production stability. The company supports global aviation platforms with aerospace cable assemblies used where continuity and risk mitigation are paramount.

The company’s strength lies in its ability to manage complex, multi-year aerospace programs across multiple sites while maintaining consistent execution. TT Electronics’ manufacturing model is optimized for volume, program longevity and contractual rigor, making it a strong match for prime contractors and Tier One suppliers operating at a global scale.

Aerospace cable assemblies are produced within International Traffic in Arms Regulations (ITAR)-registered, AS9100-certified environments, reinforcing suitability for high-assurance aviation and defense applications. While this enterprise scale brings significant capability, it can introduce less flexibility for smaller or fast-changing projects.

| Pros | Cons |

|---|---|

| ✅ Strong presence across aerospace and defense industries. | ❌ Enterprise scale may reduce flexibility for small projects. |

| ✅ Capable of supporting large-scale aerospace programs. | |

| ✅ Experience with critical applications and avionics systems. |

8. Technical Cable Applications

Technical Cable Applications is best suited for aerospace and defense programs that require specialized cable performance in extreme operating conditions. The company focuses on aerospace cable assemblies engineered to function reliably under environmental stresses that go beyond standard aircraft applications, including military and space platforms.

Rather than offering broad, high-volume manufacturing coverage, TCA concentrates on cable solutions where materials, construction methods and performance characteristics must be tailored to survive harsh environmental demands. This makes the company a strong fit for programs with unique operating profiles that cannot rely on generic aerospace assemblies.

Manufacturing is aligned with AS9100 quality expectations, supporting defense and aerospace customers that require disciplined execution and proven reliability. While TCA’s narrower scope may not suit large, multi-platform aviation programs, its depth in specialized cable performance makes it valuable for mission profiles with non-standard requirements.

| Pros | Cons |

|---|---|

| ✅ Suitable for military and space cable applications. | ❌ Narrower scope compared to large aerospace manufacturers. |

| ✅ Focus on cables designed to withstand extreme conditions. | |

| ✅ Experience supporting unique aerospace requirements. |

9. Wiringo

Wiringo stands out as an idea partner for early-stage aerospace programs and lower-volume aircraft applications where designs are still evolving. The company’s strength lies in supporting custom wire harness and cable assembly builds that require adaptability and quick adjustments during development.

Rather than optimizing for large-scale aerospace production, Wiringo focuses on flexibility and responsiveness. This makes it a solid option for smaller aerospace companies, startups or program teams refining designs before committing to long-term production or transitioning to larger manufacturers.

Wiringo maintains alignment with aerospace industry expectations while prioritizing accessibility and iteration speed. For programs that value hands-on support and the ability to evolve specifications without heavy process overhead, Wiringo provides a practical entry point into aerospace cable assembly manufacturing.

| Pros | Cons |

|---|---|

| ✅ Strong flexibility for custom design and evolving aerospace programs. | ❌ Not optimized for large-scale aerospace production. |

| ✅ Suitable for prototype and low-volume aircraft cable assemblies. | |

| ✅ Accessible option for smaller aerospace companies. |

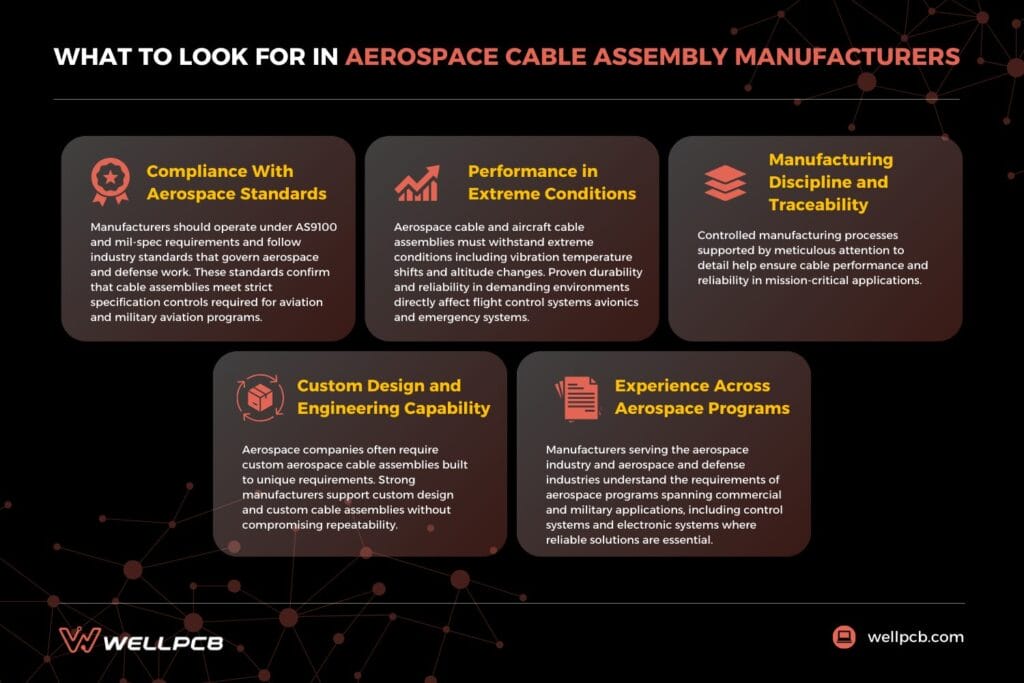

What to Look for in Aerospace Cable Assembly Manufacturers

Selecting aerospace cable assembly manufacturers requires deeper scrutiny than most industrial categories. Aerospace programs depend on cable assemblies that perform flawlessly in mission-critical systems where failure is not an option. These factors matter most when evaluating manufacturers for aerospace applications.

Compliance With Aerospace Standards

Manufacturers should operate under AS9100 and mil-spec requirements and follow industry standards that govern aerospace and defense work. These standards confirm that cable assemblies meet strict specification controls required for aviation and military aviation programs.

Performance in Extreme Conditions

Aerospace cable and aircraft cable assemblies must withstand extreme conditions including vibration temperature shifts and altitude changes. Proven durability and reliability in demanding environments directly affect flight control systems avionics and emergency systems.

Manufacturing Discipline and Traceability

Controlled manufacturing processes supported by meticulous attention to detail help ensure cable performance and reliability in mission-critical applications. Documentation traceability and configuration control are essential for cables and assemblies used across various aircraft systems.

Custom Design and Engineering Capability

Aerospace companies often require custom aerospace cable assemblies built to unique requirements. Strong manufacturers support custom design and custom cable assemblies without compromising repeatability.

Experience Across Aerospace Programs

Manufacturers serving the aerospace industry and aerospace and defense industries understand the requirements of aerospace programs spanning commercial and military applications, including control systems and electronic systems where reliable solutions are essential.

Back to Top: Top Aerospace Cable Assembly Manufacturers